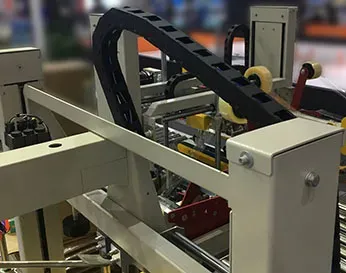

cnc drag chain

Understanding CNC Drag Chains An Essential Component in Modern Machinery

In the realm of advanced manufacturing, CNC (Computer Numerical Control) machines play a pivotal role in producing intricate components with precision and accuracy. Among various components that optimize the performance of CNC machines, drag chains serve as a critical element, ensuring the smooth operation of cables and hoses while preventing tangling and damage. This article will delve into the significance of CNC drag chains, their construction, applications, and benefits.

What Are CNC Drag Chains?

CNC drag chains, commonly referred to as cable carriers or energy chains, are mechanical systems designed to guide and protect moving cables and hoses in CNC machinery. These chains are engineered to ensure that the cables are kept organized, allowing for the smooth operation of the machine’s moving parts. They are typically made of durable plastics or metals and come in various sizes and configurations to accommodate different CNC applications.

Key Features of CNC Drag Chains

1. Durability CNC drag chains are designed to withstand the rigors of constant movement. The materials used in their construction, typically high-strength polymers or metals, provide resilience against wear and tear, ensuring a long service life.

2. Flexibility These chains can be configured to accommodate various cable and hose arrangements, making them adaptable to different machinery setups. They can be divided into multiple compartments, allowing for organized routing of different types of cables.

3. Noise Reduction When cables rub against other surfaces during movement, they can create noise that disrupts the working environment. Many drag chains include features that minimize this noise, enhancing the overall work atmosphere.

4. Ease of Installation and Maintenance Modern CNC drag chains are designed for easy installation and maintenance. They often feature a modular design that allows for quick assembly and disassembly, facilitating repairs and upgrades.

5. Space-Saving Design Efficient space management is critical in CNC environments where machinery is often closely packed. Drag chains offer a compact solution, keeping cables neatly contained and reducing the risk of entanglement.

Applications of CNC Drag Chains

CNC drag chains are utilized across various industries where CNC machines are employed, including

cnc drag chain

- Manufacturing They are essential in milling, drilling, and lathe machines, where they help manage the cables that power and control the equipment. - Robotics In robotic applications, drag chains are vital for guiding power and communication cables, ensuring the robots operate efficiently and effectively.

- 3D Printing With the increase in additive manufacturing, drag chains are increasingly being used in 3D printers to manage multiple cables, maintaining order and preventing disruptions during printing.

- Automotive and Aerospace In the automotive and aerospace sectors, CNC drag chains help in routing cables for various automated processes, contributing to streamlined production lines.

Benefits of Using CNC Drag Chains

1. Increased Productivity By preventing cable tangling and damage, drag chains help maintain consistent machine operation, which in turn increases overall productivity.

2. Enhanced Safety A well-organized cable management system reduces the risk of accidents caused by tripping or equipment malfunctions associated with damaged cables.

3. Cost-Effectiveness By extending the lifespan of cables and hoses, CNC drag chains can lower maintenance costs and reduce downtime, ultimately leading to significant savings.

4. Improved Performance Ensured proper routing of cables allows for better responsiveness of CNC machines, improving overall performance in precision tasks.

5. Customizability Many manufacturers offer customizable drag chains that meet specific operational needs, allowing businesses to tailor their cable management systems.

Conclusion

CNC drag chains are a vital component within the toolkit of modern manufacturing, playing an essential role in the operation and longevity of CNC machines. By facilitating efficient cable management, enhancing safety, and promoting productivity, drag chains contribute to the seamless functioning of various automated processes. As industries continue to evolve, the importance of such innovative solutions in enhancing machine performance and efficiency cannot be overstated. Investing in high-quality CNC drag chains can lead to not only improved operation but also significant long-term benefits for any manufacturing business.