CNC Drag Chain Solutions for Efficient Cable Management in Machinery

Understanding CNC Drag Chains Essential for Efficient Machinery Operation

In the realm of automation and machine tool operation, CNC (Computer Numerically Controlled) technology has revolutionized the manufacturing process. One of the pivotal components that enhances the efficiency and reliability of CNC machines is the drag chain. Drag chains, also known as cable carriers or energy chains, are essential for the organization and protection of cables and hoses within dynamic systems.

What is a CNC Drag Chain?

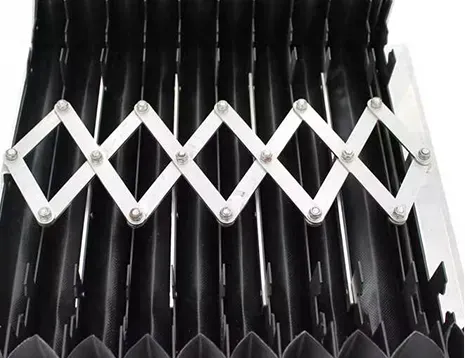

A CNC drag chain is a flexible, segmented channel that guides and protects moving cables, hoses, and pipes in machinery. These chains are designed to accommodate various types of media, including electrical cables, pneumatic lines, and hydraulic hoses. By keeping these components organized and guarded from abrasion, tangling, and other forms of wear and tear, drag chains are pivotal in ensuring the longevity of machine components and reliability in operations.

The Importance of Drag Chains in CNC Machines

CNC machines often involve complex movements that can lead to wear on cables if left unprotected. As the machine operates, the drag chain moves in tandem with the machine's axes, allowing for smooth cable movement while avoiding excessive bending or twisting. The significance of incorporating drag chains in CNC machinery cannot be understated

1. Protection Against Damage By providing a protective barrier, drag chains shield cables and hoses from physical damage caused by friction or environmental factors. This protection reduces downtime related to cable maintenance and replacements.

2. Organized Cable Management Drag chains help maintain an organized layout within the machinery. Tangles and knots can lead to interruptions in operation or even catastrophic failures. A well-structured drag chain promotes a clean and efficient machine setup.

3. Enhanced Mobility These chains are specifically designed for dynamic use. They facilitate continuous movement without the risk of cables snagging or being pulled, ensuring that CNC machinery operates smoothly and efficiently under various conditions.

cnc drag chain

4. Reduced Maintenance Costs By prolonging the life of cables and hoses, drag chains significantly reduce the costs associated with maintenance and replacement. The upfront investment in drag chain systems pays off in the long run through enhanced machine reliability.

Selecting the Right Drag Chain

When it comes to selecting the appropriate drag chain for CNC applications, several factors must be considered

- Size and Load Capacity The drag chain must be compatible with the size and weight of the cables and hoses it carries. Be sure to check the manufacturer’s specifications regarding load capacity.

- Flexibility and Bending Radius Different CNC machines have varying movement patterns. The drag chain's flexibility and minimum bending radius should match the machine's movement to avoid kinking.

- Material Drag chains are typically made from plastic or metal. Plastic chains are lighter and suitable for most applications, while metal chains provide extra durability for harsher environments.

- Environmental Resistance Consider the operating environment. Drag chains that need to operate in extreme temperatures or environments filled with chemicals will require specific materials to ensure longevity.

Conclusion

CNC drag chains are an essential component in modern CNC machining, offering protection, organization, and efficiency. As technology advances and machine designs grow more complex, the role of drag chains becomes even more critical. Investing in high-quality drag chains not only enhances machine performance but also contributes to overall operational success and cost efficiency. Ultimately, understanding and implementing the right drag chain system is fundamental for any enterprise aiming for excellence in CNC machining.