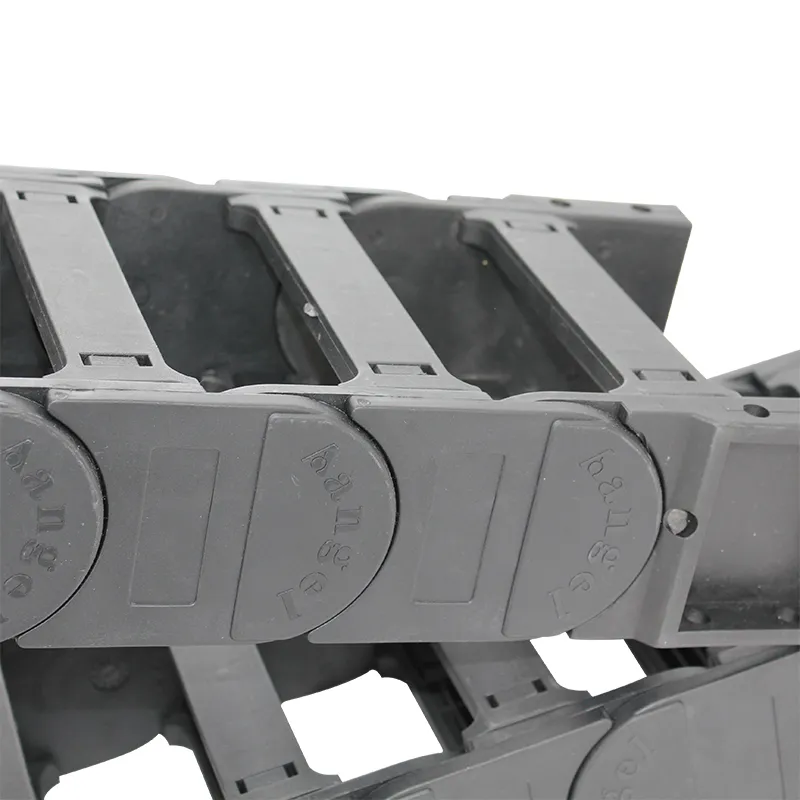

cnc cable drag chain

CNC cable drag chains, integral components in automated machinery systems, are essential for the efficient and safe management of cables and hoses. In the world of manufacturing and automation, maintaining the optimal operation of CNC machines relies heavily on these drag chains to protect cables from wear and tear, tangling, and other operational hazards. Their design allows cables and hoses to move freely and evenly with the moving parts of the machinery, preventing downtime and enhancing the machine's lifespan.

In practice, the installation of a cable drag chain system begins with a meticulous analysis of the machine’s motion dynamics and an inventory of all necessary cables and hoses. Following the principle of separating electrical wires from hydraulic hoses, we design the cable arrangement within the drag chain to minimize electromagnetic interference and prevent physical damage. Our expertise extends to retrofitting and upgrading existing systems with new innovations like self-lubricating links, which reduce maintenance time and ensure smoother operations. Ultimately, the role of CNC cable drag chains transcends mere cable protection. They are pivotal in maintaining the rhythm and pace of manufacturing processes. Each chain installation is a blend of art and science, dictated by precise calculations and creative problem-solving to seamlessly integrate with existing systems. Advocating for the best products while being manufacturers who push for their continuous improvement, we remain committed to enhancing the productivity and safety of CNC operations worldwide. End-users benefit from increased machine uptime and reduced maintenance costs, both direct reflections of effective cable drag chain solutions. As pioneers in the field, we continuously seek to innovate our offerings, ensuring that each chain not only sustains but elevates the productivity standards expected in today’s rapidly evolving industrial landscapes.

In practice, the installation of a cable drag chain system begins with a meticulous analysis of the machine’s motion dynamics and an inventory of all necessary cables and hoses. Following the principle of separating electrical wires from hydraulic hoses, we design the cable arrangement within the drag chain to minimize electromagnetic interference and prevent physical damage. Our expertise extends to retrofitting and upgrading existing systems with new innovations like self-lubricating links, which reduce maintenance time and ensure smoother operations. Ultimately, the role of CNC cable drag chains transcends mere cable protection. They are pivotal in maintaining the rhythm and pace of manufacturing processes. Each chain installation is a blend of art and science, dictated by precise calculations and creative problem-solving to seamlessly integrate with existing systems. Advocating for the best products while being manufacturers who push for their continuous improvement, we remain committed to enhancing the productivity and safety of CNC operations worldwide. End-users benefit from increased machine uptime and reduced maintenance costs, both direct reflections of effective cable drag chain solutions. As pioneers in the field, we continuously seek to innovate our offerings, ensuring that each chain not only sustains but elevates the productivity standards expected in today’s rapidly evolving industrial landscapes.