CNC Cable Chain Solutions for Efficient Machinery Organization and Protection

Understanding CNC Cable Chains Essential Components for Modern Automation

In the ever-evolving world of manufacturing and automation, CNC (Computer Numerical Control) machines play a pivotal role in driving efficiency and precision in production processes. One of the key components that contribute to the smooth operation of these machines is the CNC cable chain, also known as drag chains, energy chains, or cable carriers. These innovative systems facilitate the management of cables and hoses, ensuring that they are securely organized, well-protected, and able to move freely alongside machinery without interference.

What is a CNC Cable Chain?

A CNC cable chain is a modular, flexible system designed to house and organize various cables, hoses, and pipes used in CNC machines. These chains are engineered to allow for the smooth movement of the connected components, supporting the machine's operations while minimizing wear and tear. The primary function of a cable chain is to keep cables and hoses tidy, preventing tangling and damage, which could lead to interruptions in production or costly repairs.

Benefits of Using CNC Cable Chains

1. Organization and Efficiency One of the most significant advantages of using cable chains is that they dramatically improve the organization of a workspace. By keeping cables and hoses neatly arranged, operators can easily access connections and perform maintenance. This organized layout enhances workflow efficiency and minimizes the time spent troubleshooting issues related to tangled or damaged cables.

2. Durability and Protection CNC cable chains are constructed from robust materials designed to withstand the rigors of industrial environments. They protect cables from abrasion, stress, and environmental factors such as oil, dust, and chemicals. This protection significantly extends the lifespan of cables and hoses, reducing the frequency of replacements and maintenance.

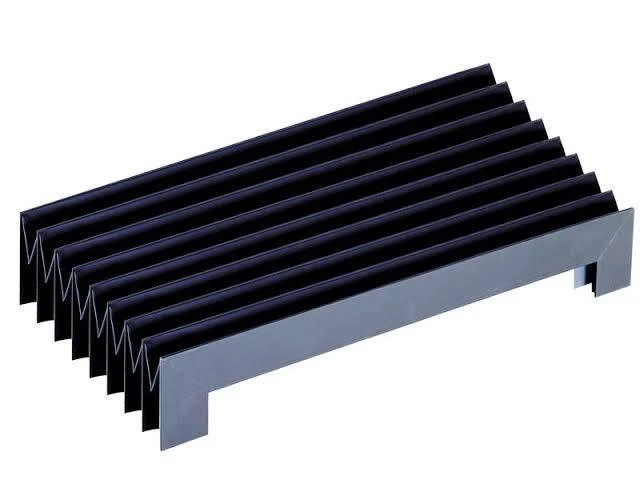

cnc cable chain

3. Enhanced Mobility CNC machines often require the movement of cables and hoses due to the dynamic nature of their operations. Cable chains are designed to flex and bend, allowing for unrestricted movement. Whether the CNC machine is moving along a linear path or pivoting, cable chains ensure that the cables remain intact and functional.

4. Customization CNC cable chains come in various sizes, shapes, and configurations, allowing manufacturers to find a solution that fits their specific needs. Customization can include different link sizes, materials, and internal layouts, enabling users to tailor the cable chain to their existing equipment.

5. Cost-Effectiveness Investing in high-quality CNC cable chains contributes to long-term cost savings. By minimizing cable wear, reducing downtime, and preventing equipment failures, these systems help maintain production schedules and enhance the overall efficiency of the manufacturing process.

Applications of CNC Cable Chains

CNC cable chains are used across various industries, including automotive, aerospace, electronics, and robotics. In CNC milling machines, lathes, and laser cutters, they play a crucial role in managing the power and signal wires associated with motors, sensors, and other operational components. These applications highlight the versatility and necessity of cable chains in modern manufacturing systems.

Conclusion

CNC cable chains are an integral part of the automation landscape, contributing to the seamless operation of CNC machines. By offering organization, protection, mobility, customization, and cost-effectiveness, these systems are indispensable for manufacturers seeking to enhance productivity and maintain high operational standards. As technology continues to advance, the role of CNC cable chains will only grow in importance, driving innovation and efficiency in industrial settings. Investing in quality cable chains is not just a smart choice; it is a commitment to the future of manufacturing excellence.