cnc cable carrier

CNC Cable Carrier An Essential Component for Modern Machinery

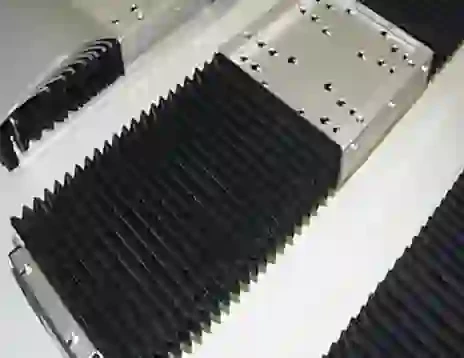

In the realm of modern manufacturing and automation, the efficiency and reliability of machinery are paramount. One of the critical components that contribute to the seamless operation of CNC (Computer Numerical Control) machines is the CNC cable carrier. Also known as energy chains, these cable carriers are integral to protecting and managing the numerous cables and hoses that power and control various aspects of machinery.

What is a CNC Cable Carrier?

A CNC cable carrier is a flexible conduit that houses electrical cables, pneumatic hoses, and hydraulic lines. Designed for moving machinery, these carriers ensure that all connected cables remain organized, protected from physical damage, and free from tangling or snagging during operation. Their primary function is to provide support and mobility for the cables as the machine moves, particularly in applications involving multi-axis motion.

The design of a CNC cable carrier usually features a modular structure, allowing for customization based on specific operational needs. Manufacturers can choose from various styles and sizes of carriers to accommodate the types and quantity of cables involved in their operations. This flexibility makes them suitable for a wide range of applications, including milling, engraving, and laser cutting.

Benefits of Using CNC Cable Carriers

1. Protection One of the most significant advantages of utilizing a cable carrier is the protection it offers. The enclosing structure helps prevent dust, dirt, and debris from settling on the cables, thus reducing the risk of wear and tear. Additionally, it safeguards against potential damage from mechanical components, ensuring a longer lifespan for both the cables and the machinery.

2. Organization Maintaining an orderly workspace is crucial in any manufacturing environment. Cable carriers enable streamlined organization, preventing the jumbled masses of wires that can complicate operations and create potential hazards. By keeping cables neatly arranged, operators can troubleshoot more efficiently and conduct maintenance with ease.

cnc cable carrier

3. Fluidity of Movement CNC machines often involve complex movements across various axes. A cable carrier allows for free movement without obstruction, ensuring smooth motion that boosts overall performance. Whether the machine is moving vertically, horizontally, or interchangeably, the cable carrier adapts to those movements, alleviating mechanical strain on the cables.

4. Noise Reduction The friction caused by moving cables can produce unwanted noise, which not only distracts operators but also indicates potential issues in machinery. By utilizing a cable carrier, this friction is minimized, leading to a quieter operational environment and reducing the likelihood of cable damage.

5. Reduced Wear and Tear The cyclic movement of motion presents a risk for cables if they are not adequately supported. With a cable carrier, cables endure less stress, as they are prevented from bending excessively or rubbing against other surfaces. This reduction in strain translates into lower maintenance costs and fewer operational downtimes.

Considerations for Selection

When selecting a CNC cable carrier, several factors must be evaluated. These include the required length and width of the carrier, the type of cables being used, the motion range of the CNC machine, and the operational environment (e.g., temperature, potential exposure to chemicals). Furthermore, it's essential to choose materials that provide the necessary durability and flexibility to withstand the rigors of industrial applications.

Conclusion

In summary, CNC cable carriers play a pivotal role in the operation of modern CNC machinery. By providing protection, organization, and fluidity of movement, they enhance the overall efficiency of manufacturing processes. As the demand for precision and reliability continues to rise in the manufacturing sector, investing in high-quality cable carriers will remain a critical consideration for businesses aiming to optimize their operations and maintain competitive edges in the market.