cnc bellow cover

Understanding CNC Bellow Covers A Comprehensive Overview

CNC (Computer Numerical Control) machines are integral to modern manufacturing, enabling precision engineering and the creation of complex parts across various industries. To protect these intricate machines and ensure their longevity, components such as bellow covers play a crucial role. In this article, we will explore the significance of CNC bellow covers, their types, materials used, and their impact on machine performance and maintenance.

What Are CNC Bellow Covers?

Bellow covers, commonly referred to simply as “bellows,” are protective coverings designed to shield the moving parts of CNC machines. They typically encase the rails, spindles, and other vital components, providing an essential barrier against dust, debris, lubricants, and other environmental contaminants. This protective gear ensures that the machine operates smoothly and maintains precision during intricate machining processes.

Importance of Bellow Covers

The primary function of bellow covers is to provide protection. By shielding sensitive components from foreign particles, they help maintain the accuracy of the CNC machine. Contaminants can lead to wear and tear on machine parts, which may result in costly repairs and downtime. Additionally, bellows are instrumental in preventing the loss of lubricants that keep the machine’s moving parts running smoothly.

Another critical aspect is the safety of the operators. Bellow covers serve as a barrier between moving parts and human operators, reducing the risk of accidents. By concealing potentially hazardous components, bellows contribute to a safer working environment.

Types of CNC Bellow Covers

CNC bellow covers come in various designs and shapes, tailored to specific applications. Here are some common types

1. Round Bellows Typically used for cylindrical components, round bellows are designed to expand and contract while maintaining a tight seal. They are most frequently found in lead screws and ball screws.

2. Square Bellows These are suitable for linear applications where motion is primarily horizontal or vertical. Square bellows can be customized to fit various machine sizes and configurations.

cnc bellow cover

3. Accordion Bellows With a design reminiscent of an accordion, these bellows provide flexibility and are commonly used in environments that require extensive movement. They can be stretched or compressed without compromising their structural integrity.

4. Custom Bellows In many cases, manufacturers require specific designs that fit unique applications. Custom bellow covers are crafted according to dimensions and operational requirements, ensuring optimal protection.

Materials Used in Bellow Covers

The choice of material for bellow covers is crucial, as it can significantly impact durability and performance. Common materials include

- Rubber Known for its elasticity and resistance to wear, rubber bellows are often used in environments that require flexibility and a strong seal against contaminants.

- Polyurethane This material offers excellent abrasion resistance and is often utilized in applications with harsh chemicals or extreme temperatures.

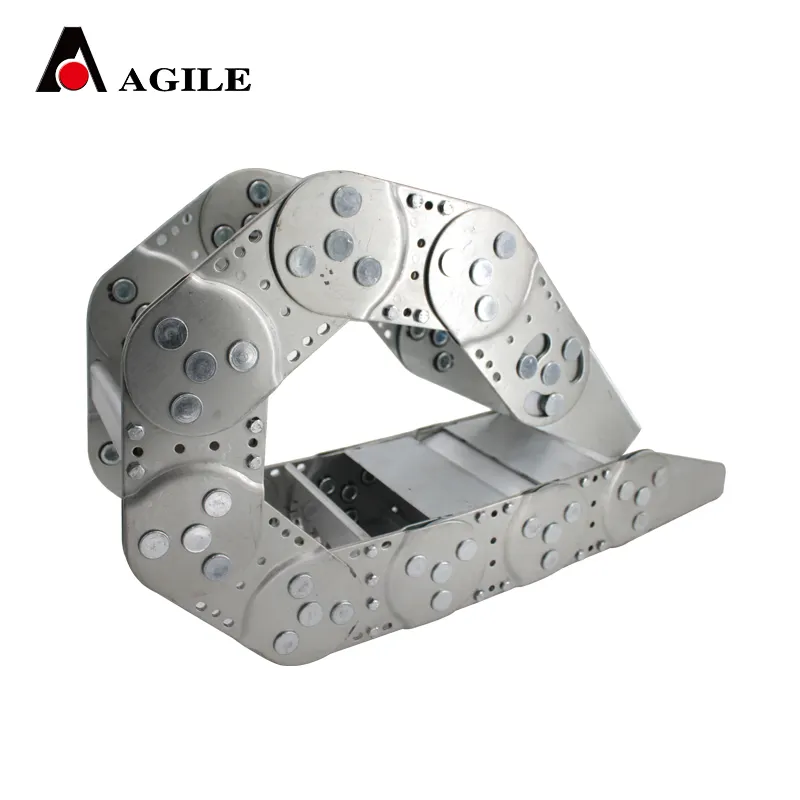

- Metal For heavy-duty applications, metal bellows (typically made of stainless steel or aluminum) provide robust protection and can withstand high temperatures and pressures.

- Fabric Some bellow covers are made from fabric-like materials that combine flexibility with a lightweight design, suitable for applications where weight is a concern.

Conclusion

CNC bellow covers represent a small yet vital component of CNC machinery, serving multiple functions that ultimately contribute to operational efficiency and safety. By providing protection against dust and debris, preventing lubricant loss, and ensuring the safety of operators, they play an indispensable role in the manufacturing process. As technology continues to advance and industries evolve, the design and materials used in bellow covers will continue to improve, further enhancing the performance and longevity of CNC machines. Understanding and investing in quality bellow covers is an essential step for manufacturers aiming to optimize their production capabilities while minimizing downtime and maintenance costs.