Optimizing Performance with Closed Drag Chain Innovations and Applications

Understanding Closed Drag Chains An Overview

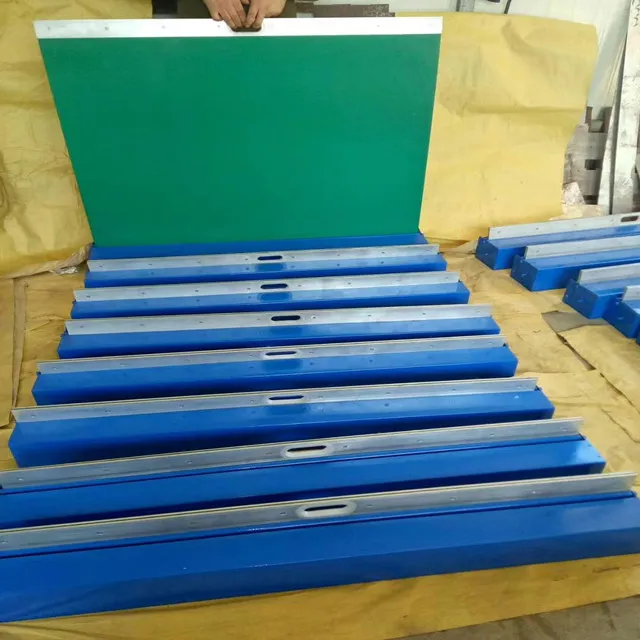

Closed drag chains, often utilized in various industrial applications, serve as crucial components for efficiently managing and organizing cables, hoses, and other flexible elements within machinery and equipment. These specialized systems help protect sensitive components from environmental hazards, physical wear, and tangling, thereby ensuring smooth operations and prolonging the lifespan of critical elements.

A closed drag chain consists of interconnected links that form a protective enclosure around cables or hoses, creating a continuous loop. The design allows for unrestricted movement while maintaining a neat organization, making it ideal for dynamic applications where movement is required. Whether it’s in automated manufacturing lines, CNC machines, or robotic systems, closed drag chains facilitate the reliable transmission of power and data, even in high-speed and high-load situations.

The benefits of using closed drag chains are extensive. Firstly, they help to reduce wear and tear on cables and hoses by providing a stable route and preventing excessive bending or twisting. This is particularly important in environments where equipment undergoes frequent movement, as it minimizes the risk of cable fatigue and potential failures. Additionally, closed drag chains can protect cables from dust, debris, and other environmental factors, thus enhancing overall durability.

closed drag chain

Moreover, closed drag chains can be customized to fit specific applications

. They come in various sizes, shapes, and materials, including plastic and metal, which allows users to choose the best option based on their needs. Some chains feature additional accessories, such as mounting brackets and strain relief systems, further enhancing their functionality and ease of installation.In terms of installation, closed drag chains are designed for user-friendly set-up. They can be easily integrated into existing systems, and the modular design allows for quick adjustments to be made as project requirements evolve. This adaptability is a significant advantage in fast-paced manufacturing environments where downtime can lead to considerable financial losses.

Maintenance of closed drag chains is relatively straightforward. Regular inspections help ensure that the chains remain in optimal condition, preventing potential issues before they develop into significant problems. Furthermore, their durability means they often require less frequent replacements compared to other types of cable management solutions.

In summary, closed drag chains play a pivotal role in enhancing the efficiency and safety of cable management within various industrial applications. Their protective features, customizability, and ease of integration make them a vital component in modern machinery, contributing to seamless operations and reducing the risk of mechanical failure. As industries continue to innovate, the demand for such efficient and reliable solutions will only increase, reinforcing the importance of closed drag chains in the contemporary engineering landscape.