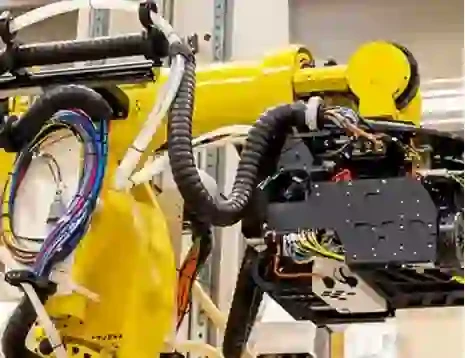

closed drag chain

Understanding Closed Drag Chains A Comprehensive Guide

In the world of industrial machinery and automation, efficient movement and protection of cables and hoses are paramount. Closed drag chains, also known as energy chains, play a crucial role in ensuring the smooth operation of machinery while safeguarding vital components from abrasion and environmental factors. This article delves into the characteristics, benefits, and applications of closed drag chains, making them an essential element in various industries.

What Are Closed Drag Chains?

Closed drag chains are flexible conduits designed to hold and guide cables, hoses, and other components in motion. Unlike open drag chains, which expose the cables to the external environment, closed drag chains completely encase the cables within a protective shell. This design not only enhances safety but also extends the lifespan of the cables by preventing wear and tear caused by friction, dirt, and exposure to harsh conditions.

Key Features

1. Protection The primary function of closed drag chains is to keep cables and hoses organized and protected during movement. The closed structure shields them from dust, debris, moisture, and mechanical damage.

2. Flexibility Closed drag chains are designed to allow for dynamic movement, making them suitable for applications where cables must bend and flex. This flexibility is essential in robotics, CNC machines, and automated production lines.

3. Variety of Sizes Closed drag chains come in various sizes and configurations, making it easy to select the right chain based on the dimensions and weight of the cables being used. This versatility ensures compatibility with a wide range of machinery and equipment.

4. Ease of Installation Many closed drag chains are designed for user-friendly installation. With modular components, they can be assembled quickly and efficiently, minimizing downtime during setup.

5. Customizability Manufacturers often provide customization options for closed drag chains, allowing businesses to tailor the chains to their specific needs, including features like additional guide channels or specialized materials for extreme environments.

closed drag chain

Benefits of Closed Drag Chains

1. Increased Lifespan of Cables By minimizing friction and environmental exposure, closed drag chains significantly extend the life of the cables and hoses they protect. This leads to reduced maintenance costs and less frequent replacements.

2. Enhanced Safety Closed drag chains help prevent accidents by keeping cables organized and out of the way, reducing tripping hazards and ensuring a cleaner work environment.

3. Improved Efficiency With cables neatly managed and protected, machinery operates more smoothly and efficiently. This can lead to increased productivity within an organization.

4. Cost-Effective Solution While there may be an initial investment in closed drag chains, the long-term benefits, including reduced downtime, minimized maintenance, and extended cable life, make them a cost-effective solution for businesses.

Applications of Closed Drag Chains

Closed drag chains are utilized in various industries, including

- Manufacturing Automated production lines and CNC machines extensively use closed drag chains to manage power and control cables. - Robotics Robots often operate in dynamic environments where movement is essential; closed drag chains help keep cables secure while allowing for fluid motion. - Material Handling In warehouses and distribution centers, closed drag chains protect cables in conveyor systems and other machinery that involve constant movement. - Automotive Industry Automotive assembly lines rely on closed drag chains to guide and protect wiring in robotic arms and conveyor systems.

Conclusion

In summary, closed drag chains are an indispensable component in modern machinery and automation. By providing a robust solution for cable management, these chains enhance safety, improve efficiency, and reduce overall costs. As industries continue to evolve and require more complex machinery, the demand for effective protective solutions like closed drag chains will undoubtedly grow. Understanding their features, benefits, and applications can help businesses make informed decisions that lead to greater productivity and operational success.