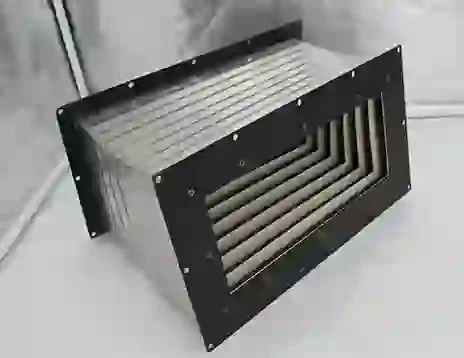

closed drag chain

Understanding Closed Drag Chains A Comprehensive Guide

In the world of engineering and machinery, the importance of efficient cable management cannot be overstated. One of the most effective solutions for managing cables, hoses, and wires is the use of drag chains—specifically, closed drag chains. This article delves into the intricacies of closed drag chains, exploring their benefits, applications, and design considerations.

What is a Closed Drag Chain?

A closed drag chain, often referred to as a cable carrier or energy chain, is a device that organizes and protects moving cables and hoses within various types of machinery. Unlike open drag chains, which expose the cables to external elements, closed drag chains feature a completely enclosed design. This enclosure serves to safeguard the contents from dirt, abrasions, and other environmental hazards, providing a crucial layer of protection that enhances the longevity of the cables and hoses.

Benefits of Closed Drag Chains

1. Protection The primary advantage of closed drag chains is the protection they provide. By enclosing the cables, they are shielded from physical damage, which can occur due to friction, dust, or exposure to chemicals. This protection minimizes the risk of cable failure, leading to reduced downtime and lower maintenance costs.

2. Aesthetic Appeal Closed drag chains can enhance the overall appearance of machinery and workspaces. With a tidy and organized look, they contribute to a more professional environment, which can be significant in settings where machinery is on display, such as manufacturing facilities or exhibitions.

3. Reduction of Noise Noise reduction is another critical benefit of using closed drag chains. Enclosed systems tend to minimize the rattling and clattering sounds associated with open cables moving over surfaces, promoting a quieter working environment.

4. Streamlined Movement Closed drag chains provide a smooth trajectory for cables and hoses during operation. This streamlined movement reduces friction, which can increase the lifespan of cables and improve overall operational efficiency.

Applications of Closed Drag Chains

Closed drag chains are versatile and can be found in various industries and applications. They are commonly used in

closed drag chain

- Industrial Automation In robotic applications, closed drag chains help in managing cables that connect the robotic arms to controllers, ensuring smooth movement and minimizing wear and tear. - CNC Machines For computer numerical control machines, these chains protect critical wiring and hoses from debris and other elements that could disrupt precision work.

- Construction Equipment In heavy machinery, closed drag chains manage hydraulic hoses and electrical cables, providing a clean and safe cable management solution.

- Packaging and Conveying Systems They are essential for efficiently routing power and signal cables within high-speed packaging and conveyor systems.

Design Considerations

When selecting a closed drag chain, engineers must consider several factors

- Size and Capacity The dimensions of the drag chain must accommodate the number and size of cables being used. It's essential to choose a chain that can handle the required load without excessive strain.

- Material Closed drag chains can be made from various materials, including plastic and metal. Each material serves different environments and workloads, so choosing the appropriate one is critical for longevity and effectiveness.

- Flexibility Depending on the application, the drag chain may need to be flexible to navigate tight turns or complex paths within machinery.

Conclusion

Closed drag chains are an invaluable component in modern machinery, providing protection, organization, and efficiency to cable management systems. Their ability to safeguard cables while ensuring smooth operational movement makes them a preferred choice across various industries. As technology continues to evolve, the designs and applications of closed drag chains will likely expand, further solidifying their role in enhancing machinery performance.