Innovative Solutions for Enhanced Closed Drag Chain Performance and Efficiency

Understanding Closed Drag Chains A Comprehensive Guide

In industrial and manufacturing environments, the movement of machinery and robotic systems is crucial for efficiency and productivity. One of the key components that facilitate smooth movement of cables, hoses, and other vital connections is the drag chain, also known as cable carriers. Among the various types available, closed drag chains stand out for their specific advantages and applications.

What is a Closed Drag Chain?

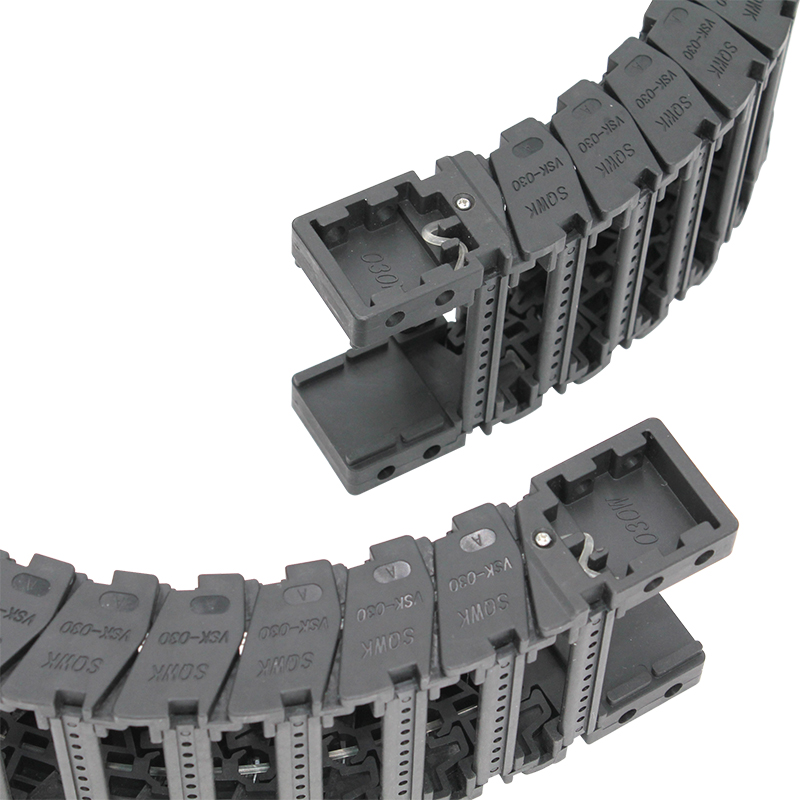

Closed drag chains are designed to enclose and protect cables and hoses, ensuring that they remain organized and free from damage during operation. Unlike open drag chains, closed variants create a fully enclosed environment, preventing debris and contaminants from entering the chain. This feature extends the lifespan of the cables and hoses, reduces maintenance costs, and enhances operating safety.

Key Features of Closed Drag Chains

1. Robust Construction Closed drag chains are typically made of durable materials such as nylon, polyurethane, or steel, making them resistant to wear and tear. Their robust construction is especially beneficial in environments with high levels of exposure to dust, oil, and extreme temperatures.

2. Cable Protection The enclosed design of closed drag chains provides superior protection for cables and hoses. They shield the contents from abrasion, crushing, and environmental factors, which is essential in applications involving heavy machinery or outdoor settings.

3. Flexibility and Movement Closed drag chains allow for a high level of flexibility in movement. They can accommodate multiple cables and hoses while maintaining minimal bending radii, which is vital for applications with tight spaces or complex trajectories.

4. Easy Installation and Maintenance Most closed drag chains are designed for easy installation. They often come with pre-drilled holes and mounting brackets, facilitating quick attachment to machinery. Additionally, maintenance is simplified as the operator can easily access the interior of the chain for repairs or replacements without needing extensive disassembly.

Applications of Closed Drag Chains

Closed drag chains are versatile and find applications in various industries

. Some common uses includeclosed drag chain

- CNC Machines In computer numerical control (CNC) machinery, closed drag chains help to organize and protect power and data cables, ensuring that they do not interfere with moving parts.

- Robotics In robotic systems, these chains ensure that cables for sensors and power supplies remain secure and protected during movement, reducing the risk of damage that can lead to system failures.

- Automated Production Lines Closed drag chains are essential in automated manufacturing setups, ensuring that various cables and hoses used for pneumatic systems or electrical operations are well-organized and safe from potential hazards.

Benefits of Using Closed Drag Chains

The use of closed drag chains brings several key benefits to industrial operations

- Enhanced Safety By keeping cables and hoses contained and organized, closed drag chains help reduce the chances of tangling or accidental disconnections, enhancing safety for operators.

- Reduced Downtime With better protection and organization of cables and hoses, closed drag chains minimize the risk of unexpected failures and repairs, resulting in less equipment downtime and increased productivity.

- Cost Efficiency Though the initial investment in closed drag chains may be higher than for simpler solutions, the long-term savings from reduced maintenance and prolonged equipment life make them a cost-effective choice.

Conclusion

Closed drag chains play a vital role in modern industrial applications, providing essential protection and organization for cables and hoses. Their durability, flexibility, and safety features make them a preferred choice for many industries. Whether in robotics, CNC machines, or automated production lines, investing in closed drag chains can lead to enhanced operational efficiency and significant cost savings in the long run. As technology continues to evolve, the importance of such components in maintaining seamless operations will only increase, marking them as a critical element in the future of industrial design and engineering.