Closed Drag Chain - Efficient Cable Management Solutions

The Significance of Closed Drag Chains in Modern Industries

In the realm of engineering and manufacturing, the efficient management of cables and hoses is critical for the smooth operation of machinery and equipment. One of the most innovative solutions for this purpose is the closed drag chain. These structures, also known as cable carriers or drag chains, play an essential role in protecting and organizing moving cables and hoses in various industrial applications.

Closed drag chains are designed to guide cables and hoses in a controlled manner, significantly reducing wear and tear that can occur from friction and environmental exposure. Unlike open drag chains, closed variants completely encase the cables and hoses, providing an additional layer of protection from dirt, debris, and other external elements. This enclosed design not only prolongs the life of the cables but also enhances safety by minimizing the risks of cable damage or entanglement.

One of the key advantages of closed drag chains is their versatility. They can be employed in a multitude of environments, from heavy machinery in manufacturing plants to automated systems in warehouses. Additionally, they are commonly used in robotic applications, CNC machines, and even in wind turbine operations, showcasing their adaptability across various fields.

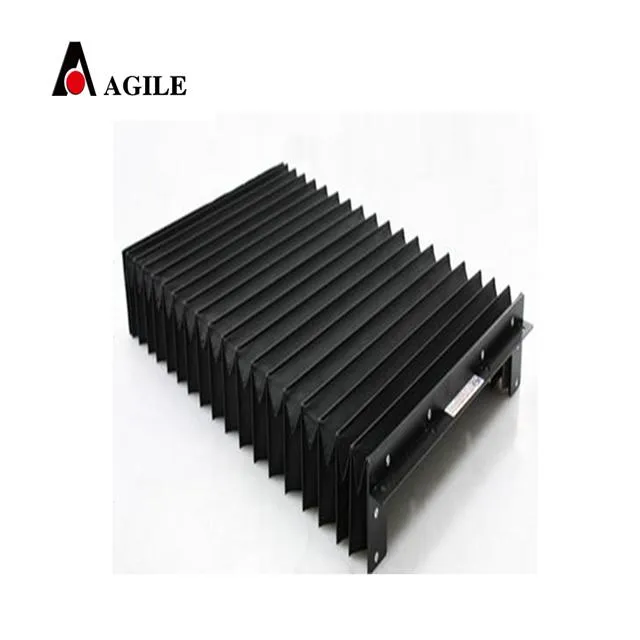

closed drag chain

From a design perspective, closed drag chains are engineered with specific considerations to optimize performance. They are typically made from durable materials such as plastic or metal, chosen for their strength and resistance to wear. Furthermore, manufacturers often offer a variety of sizes and customization options, allowing companies to select a drag chain that best suits their operational needs. The ability to configure the internal layout of the chain means that multiple cables and hoses can be organized within a single assembly, reducing clutter and improving overall efficiency.

Another important aspect of closed drag chains is their contribution to reducing downtime. By keeping cables and hoses organized and protected, maintenance becomes significantly easier. Operators can quickly identify potential issues and replace worn components before they lead to equipment failure. This proactive approach is crucial, as equipment downtime can lead to substantial financial losses and a decrease in productivity.

In conclusion, closed drag chains represent a vital component in the modern industrial landscape. Their protective and organizational capabilities not only extend the life of cables and hoses but also enhance the safety and efficiency of machinery. As industries continue to prioritize automation and streamlined operations, the demand for efficient cable management solutions like closed drag chains is expected to grow. This evolution signifies a broader trend towards optimizing performance and reducing operational risks in an increasingly competitive market. By investing in advanced cable management systems, businesses can position themselves for success in the face of technological advancements and industrial challenges.