Chip Screw Conveyor Design and Applications in Material Handling Systems

Understanding Chip Screw Conveyors An Essential in Material Handling

In various industrial applications, effective material handling is crucial for maintaining productivity and efficiency. One of the innovative solutions that have gained popularity in recent years is the chip screw conveyor. Specifically designed to transport bulk materials like metal chips, the chip screw conveyor provides a reliable and efficient means of moving these often unwieldy materials around the production floor.

What is a Chip Screw Conveyor?

A chip screw conveyor is a type of mechanical device that utilizes a rotating helical screw, known as a flight, to move bulk materials from one point to another. The design typically consists of a trough or tube, which houses the screw, and is often made from robust materials to withstand the abrasiveness of the materials being handled.

The conveyor works on the principle of screw motion—when the screw rotates, the flights push the material along the trough. Whether it's metal shavings from machining processes or plastic pellets, the chip screw conveyor is adept at transporting materials swiftly and safely.

Key Features of Chip Screw Conveyors

1. Durability Chip screw conveyors are constructed from high-strength materials such as stainless steel or carbon steel, ensuring that they can handle harsh conditions and abrasive materials. This durability increases their lifespan and reduces maintenance costs.

2. Flexibility Chip screw conveyors can be designed in various configurations to suit specific industrial requirements. They can be horizontal, inclined, or even decline, enabling them to fit seamlessly into existing production lines and workflows.

3. Efficiency These conveyors are designed for continuous operation, providing a steady flow of materials without interruption. Their efficient material handling capabilities can significantly enhance productivity in industries such as automotive, metalworking, and plastics.

4. Low Maintenance With fewer moving parts compared to other types of conveyors, the chip screw conveyor requires less maintenance. Regular inspections and basic upkeep are typically sufficient to ensure optimal performance.

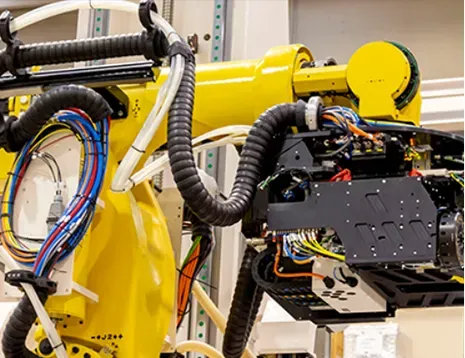

chip screw conveyor

Applications of Chip Screw Conveyors

Chip screw conveyors find applications in various industries due to their versatility and efficiency. In machine shops, for instance, they are instrumental in transporting metal chips that result from machining processes. This helps prevent material buildup, reduces fire hazards, and makes it easier to recycle scrap metal.

In the plastic injection molding industry, chip screw conveyors effectively manage resin pellets and scrap, aiding in waste reduction and ensuring a cleaner production environment. Furthermore, they can be utilized in food processing plants to convey bulk ingredients, demonstrating their adaptability across different sectors.

Benefits of Using Chip Screw Conveyors

The adoption of chip screw conveyors comes with numerous advantages

- Increased Safety By automating material handling, these conveyors minimize the risk of worker injuries associated with manual handling of heavy or sharp materials. - Enhanced Productivity Continuous and rapid transportation of materials means less downtime and higher output rates, which ultimately contribute to improved overall productivity.

- Waste Reduction For industries focused on sustainability, chip screw conveyors facilitate the easy collection and recycling of scrap materials, thus promoting eco-friendly practices.

Conclusion

In conclusion, chip screw conveyors play a vital role in modern manufacturing and processing environments. Their combination of durability, efficiency, and adaptability makes them an essential component for any production line that deals with bulk materials. As industries continue to evolve and prioritize automation and efficiency, the significance of chip screw conveyors will undeniably grow. Investing in such technology not only streamlines operations but also contributes to a safer and more productive work environment. With proper implementation and maintenance, companies can leverage the full potential of chip screw conveyors, driving success in an increasingly competitive landscape.