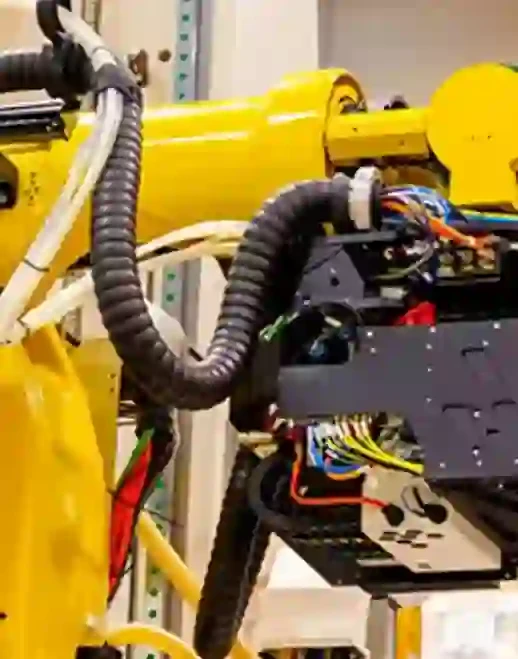

chip screw conveyor

The Efficiency of Chip Screw Conveyors in Modern Manufacturing

In the ever-evolving landscape of manufacturing and industrial processes, efficiency and reliability are paramount. One of the most vital components in the transport and management of materials in such environments is the conveyor system. Among the various types of conveyors available, chip screw conveyors have gained particular attention due to their unique advantages in handling bulk materials, especially in industries that deal with metalworking and material machining.

What is a Chip Screw Conveyor?

A chip screw conveyor, also known as a screw feeder or auger conveyor, is a specially designed machinery used for the transportation of particulate and bulk materials. The mechanism primarily consists of a rotating helical screw, often housed within a tube, which moves the material from one point to another. These conveyors are especially effective for handling chips, shavings, and other small debris generated during machining processes.

Applications in Manufacturing

The use of chip screw conveyors is prevalent across various sectors, including metalworking, woodworking, and recycling. In metalworking industries, for instance, metal chips produced by lathes, mills, and machining centers can accumulate quickly, leading to downtime and inefficiencies. A chip screw conveyor efficiently transports these chips from the machine tool to a waste bin or recycling system, minimizing cleanup time and ensuring smooth operations.

In woodworking, similar applications exist where sawdust and wood chips need to be moved swiftly to reduce waste and enhance productivity

. By incorporating chip screw conveyors, manufacturers can not only streamline their processes but also significantly reduce the labor costs associated with manual disposal of waste.Benefits of Chip Screw Conveyors

chip screw conveyor

One of the primary benefits of chip screw conveyors is their ability to handle a variety of materials with different characteristics. Whether the material is dry, wet, or varying in size, these conveyors provide a reliable solution for transporting diverse types of bulk materials. This adaptability makes them suitable for various manufacturing environments.

Another significant advantage lies in their design. Chip screw conveyors typically require less floor space than traditional belt conveyors, making them ideal for facilities where space is a constraint. Additionally, they can be installed at various angles, allowing for more innovative layouts that optimize the flow of materials.

The efficiency of chip screw conveyors extends to maintenance as well. Their simple and robust construction often leads to lower maintenance requirements compared to other conveyor types. This durability translates into prolonged service life, equating to fewer disruptions in manufacturing operations and reduced replacement costs.

Environmental Impact

In today’s eco-conscious society, manufacturing processes must also consider their environmental footprint. Chip screw conveyors facilitate recycling and waste management by efficiently transporting scrap materials to recycling centers, thus promoting sustainability in manufacturing. By reducing waste accumulation and encouraging the reuse of materials, companies can enhance their environmental responsibility while also cutting costs.

Conclusion

Chip screw conveyors play a pivotal role in modern manufacturing processes by enhancing efficiency, minimizing labor costs, and promoting sustainability. Their versatility, ease of maintenance, and compact design make them an indispensable asset in a variety of industries. As businesses continue to seek ways to improve their operations and reduce environmental impact, the importance of chip screw conveyors will only enhance, ensuring their place at the forefront of material handling technology. The synergy of these benefits positions chip screw conveyors not just as a solution, but as an essential component in the quest for manufacturing excellence.