Chip Conveyor System for Efficient Material Handling and Transportation Solutions

Understanding Chip Screw Conveyors A Comprehensive Overview

Chip screw conveyors are integral components in various industrial operations, particularly in the metalworking and machining sectors. These conveyors are specifically designed to transport metal chips, shavings, and other byproducts that result from machining processes. As industries strive for efficiency and productivity, understanding the functionality and advantages of chip screw conveyors becomes essential.

What is a Chip Screw Conveyor?

A chip screw conveyor, often referred to as a screw auger, utilizes a rotating helical screw blade to move material along a defined path. This type of conveyor is particularly effective in transporting bulk materials, making it a popular choice in facilities where metalworking and machining are conducted. The design allows for continuous movement, which minimizes the downtime that can occur during manual handling.

Key Features and Benefits

One of the primary advantages of chip screw conveyors is their ability to handle a wide variety of materials

. They can transport metal chips ranging from fine shavings to larger scrap pieces with ease. The enclosed design of these conveyors also prevents spillage and minimizes the release of airborne particles, making them a safer option for industrial environments.Moreover, chip screw conveyors are engineered for durability. Constructed from robust materials such as stainless steel or carbon steel, they are built to withstand the harsh conditions prevalent in machining environments. This durability translates into low maintenance requirements and a longer lifespan, ultimately reducing operational costs.

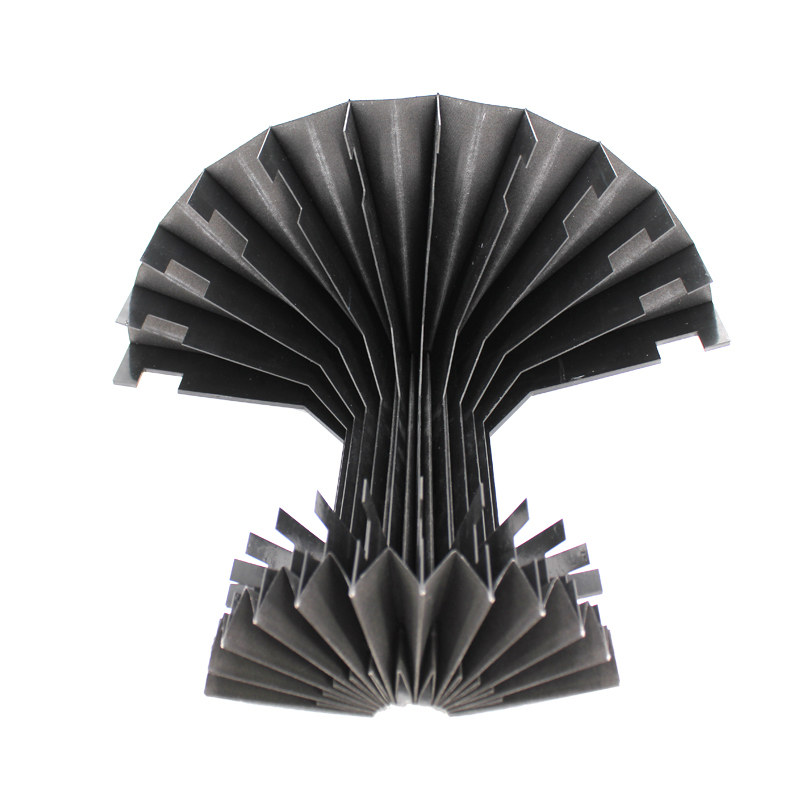

chip screw conveyor

Efficiency and Space-Saving Design

In addition to their robust design, chip screw conveyors are notable for their space-saving attributes. Unlike traditional belt conveyors, which require a substantial amount of floor space, screw conveyors can be configured to run vertically or horizontally, making them ideal for facilities with limited space. Their compact design enables seamless integration into existing processes, maximizing the efficiency of material handling systems.

Customizability

Another significant aspect of chip screw conveyors is their customizability. These conveyors can be adapted to meet specific requirements, including varying sizes, power options, and configurations. This flexibility allows manufacturers and industrial operators to tailor the equipment to their unique operational needs, ensuring optimal performance.

Conclusion

In summary, chip screw conveyors play a crucial role in enhancing operational efficiency within metalworking industries. Their ability to transport metal chips securely, coupled with their durability, space-saving design, and customizability, makes them a vital asset in any machining operation. As industries continue to evolve and seek improvement in material handling processes, chip screw conveyors will undoubtedly remain at the forefront of innovative manufacturing solutions. Investing in this technology not only streamlines operations but also supports a safer and more efficient workplace.