chip screw conveyor

The Versatility and Efficiency of Chip Screw Conveyors

In the realm of industrial engineering and material handling, chip screw conveyors have established themselves as an indispensable technology. These conveyors, which employ a helical screw blade to move bulk materials, play a critical role in various sectors, including manufacturing, mining, and agriculture. As industries evolve and demand for efficiency increases, understanding the advantages and applications of chip screw conveyors becomes essential.

What is a Chip Screw Conveyor?

A chip screw conveyor, often referred to as a screw auger or screw feeder, is a mechanical device designed for transporting bulk materials. It consists of a rotating helical screw that moves materials along a trough or tube. Chip screw conveyors are particularly effective for handling a wide range of materials, including granular, powdery, or semi-solid substances. They are commonly used for transporting metal shavings, wood chips, and various aggregates.

Advantages of Chip Screw Conveyors

One of the primary benefits of chip screw conveyors is their ability to convey materials in a compact and efficient manner. Unlike traditional belt conveyors, screw conveyors can operate at a steeper incline, allowing for vertical movement of materials with minimal space requirements. This design optimizes floor space in manufacturing facilities, warehouses, and processing plants.

Moreover, chip screw conveyors offer flexibility in design. They can be configured in various lengths, diameters, and orientations, making them suitable for a range of applications. They can also handle a variety of materials, including those that are hot, cold, abrasive, or corrosive. This adaptability makes chip screw conveyors an ideal choice for diverse industries.

Applications in Various Industries

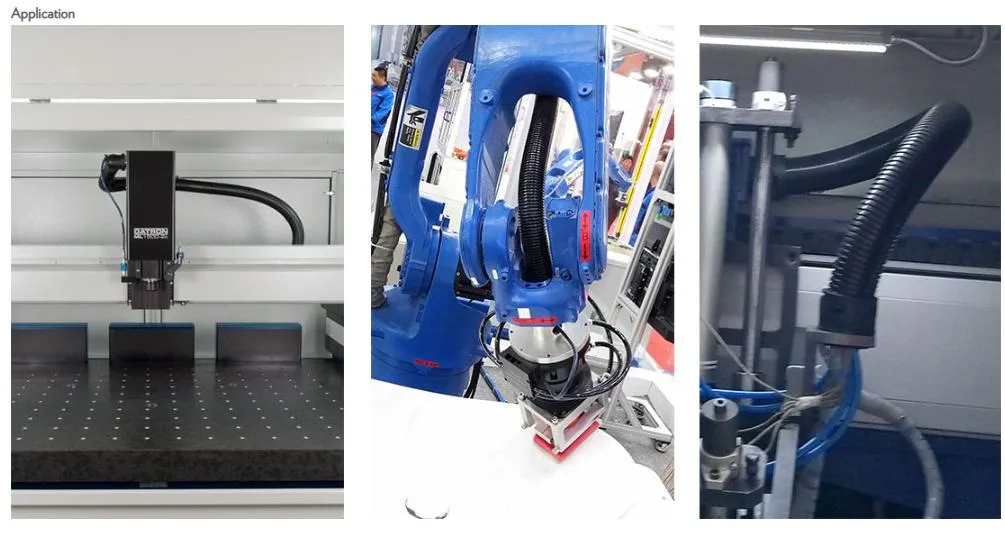

Chip screw conveyors find applications in many sectors. In manufacturing, they are often used to transport metal chips generated during machining processes. By efficiently moving these chips away from the work area, they help maintain cleanliness and safety, reducing the risk of accidents and improving worker productivity.

chip screw conveyor

In the agricultural sector, chip screw conveyors are utilized for grain handling, seed transport, and feed distribution. Their ability to convey materials gently and without degradation helps maintain product quality, which is crucial in agriculture.

Furthermore, in the waste management and recycling industries, these conveyors play a vital role in transporting scrap material to recycling centers. Their robust design allows them to handle heavy loads, making them ideal for processing plants where heavy materials are common.

Maintenance and Longevity

To ensure optimal performance and longevity, it is crucial to implement regular maintenance schedules for chip screw conveyors. This includes routine inspections of the screw, bearings, and trough for wear and damage. Lubricating moving parts is essential to prevent friction and reduce wear, ensuring smooth operation.

Moreover, operators should monitor the alignment and tension of the conveyor system to prevent overloading, which can lead to premature failure. With proper maintenance, chip screw conveyors can have a long operational life, reducing overall operational costs and downtime.

Conclusion

In summary, chip screw conveyors are a versatile and efficient solution for transporting bulk materials across various industries. Their compact design, flexibility in configuration, and ability to handle a wide range of materials make them suitable for numerous applications. As industries continue to seek ways to improve efficiency and productivity, the importance of chip screw conveyors is undoubtedly set to rise.

Understanding the operational requirements, performing regular maintenance, and recognizing the specific advantages of chip screw conveyors can significantly enhance material handling processes and contribute to overall industrial efficiency. As technology advances, it is likely that these conveyors will continue to evolve, providing even more innovative solutions for effective material transport.