CNC Machine Chip Conveyor Solutions for Efficient Waste Management

Chip Conveyor for CNC Machines Enhancing Efficiency and Productivity

In the world of CNC (Computer Numerical Control) machining, managing the byproducts of the machining process is as crucial as the machining itself. One of the significant byproducts is metal chips, which not only clutter the workplace but also can impede productivity and efficiency. A chip conveyor serves as an essential component in modern CNC machining operations, designed to remove these chips quickly and efficiently, ensuring a smoother workflow and reduced downtime.

The Importance of Chip Management

In any CNC machining environment, the continuous machining process generates a substantial amount of chips, whether from metal milling, drilling, or turning. These chips can be small or large, but regardless of size, they can cause several issues if not handled properly. If left unattended, chips can obstruct machine parts, accumulate in the workspace, and even lead to hazardous working conditions. Moreover, they can trap coolant, which is essential for the machining process, ultimately leading to overheating and wear of the cutting tools.

This is where chip conveyors come into play. By effectively transporting chips from the CNC machine to a designated disposal location, these conveyors not only help maintain a clean work environment but also ensure the machines operate at peak efficiency.

Types of Chip Conveyors

Chip conveyors come in various designs, each suited to specific machining operations and types of materials. The most common types include

1. Screw Conveyors Utilizing a rotating helical screw to move chips along a trough, screw conveyors are ideal for small to medium-sized chips. They are versatile, can be configured for continuous operation, and are easy to integrate into existing systems.

2. Magnetic Conveyors These are used for ferrous materials and are beneficial in applications where magnetic properties help keep chips aligned for transportation. They are particularly effective for handling small, thin chips.

3. Drag Chain Conveyors Designed for heavier or bulkier chips, these conveyors use a chain driven through a track to drag chips away. They are robust and can handle a significant volume, making them suitable for heavy machining operations.

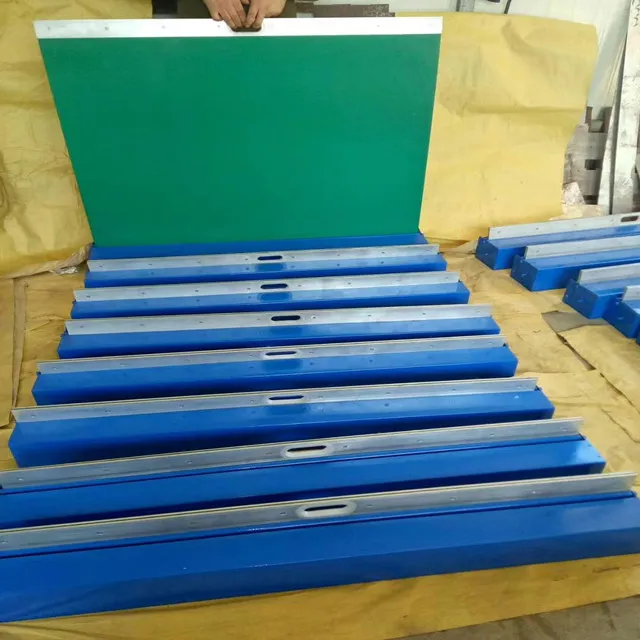

chip conveyor for cnc machine

4. Belt Conveyors A simple yet effective solution, these conveyors use a continuous belt to move chips away from the machine. They are easy to install and maintain and can be customized with various belt materials to suit different chip types.

Benefits of Installing Chip Conveyors

Investing in a chip conveyor system can lead to numerous benefits for CNC machining operations

- Increased Productivity By automatically removing chips from the machining area, operators can focus on the tasks at hand instead of spending time managing debris. This leads to enhanced productivity and more efficient use of machine time.

- Improved Tool Life Proper chip removal reduces the likelihood of chip build-up, which can cause tool damage and lead to breakdowns. This results in a longer lifespan for cutting tools and less frequent replacements.

- Cleaner Work Environment A tidy workspace is essential for safety and efficiency. Chip conveyors help maintain a clean environment, reducing the risk of accidents and enhancing employee morale.

- Reduced Downtime With chips constantly removed from the machining area, the chances of a machine needing to halt production for manual chip removal decreases significantly.

Conclusion

In the competitive landscape of CNC machining, efficiency is paramount. Chip conveyors are a vital tool that facilitates sustainable operations by ensuring that metal chips are effectively handled. With a range of designs available, manufacturers can choose the ideal chip conveyor system tailored to their specific needs, ultimately enhancing productivity, safety, and overall efficiency. As industries continue to evolve, the role of chip conveyors will likely become even more significant, making them an integral part of modern machining processes.