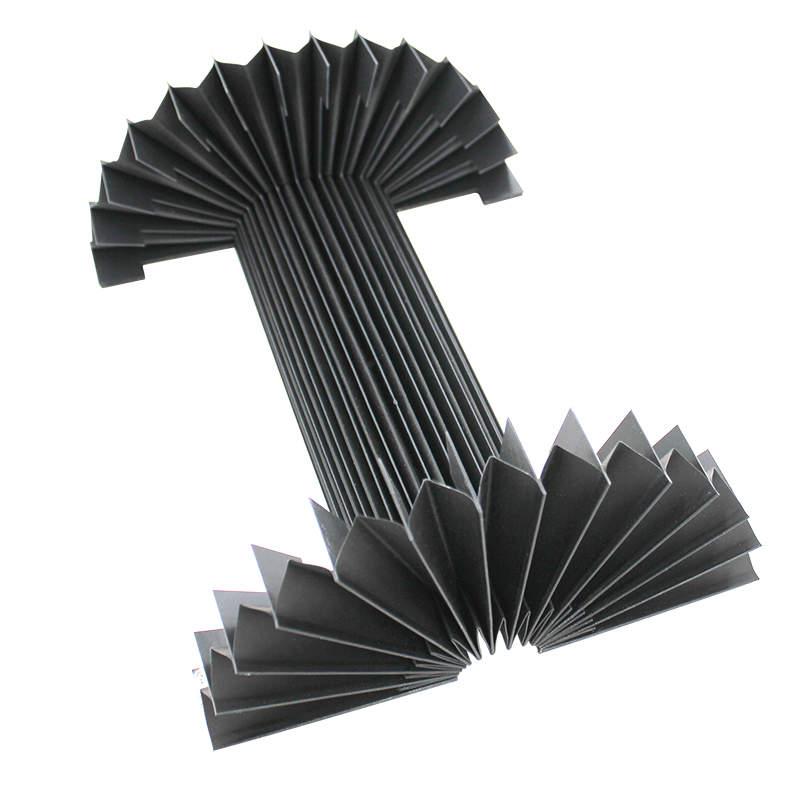

chip conveyor for cnc machine

Chip Conveyor for CNC Machines Enhancing Efficiency and Productivity

In the world of computer numerical control (CNC) machining, maintaining a clean and efficient workspace is crucial for productivity and precision. One of the vital components that contribute to this clean environment is the chip conveyor. This device plays an essential role in the removal of metal chips and other debris generated during machining operations, ensuring that production processes run smoothly and efficiently.

Why Chip Conveyors Are Essential

CNC machines are designed to produce high-precision components, but they also generate a significant amount of waste material in the form of chips. These metal chips can accumulate rapidly, negatively impacting the workflow and potentially interfering with machine operation. A chip conveyor is specifically designed to automate the removal of these chips, allowing for continuous operation of the CNC machine without the need for frequent manual cleaning.

Types of Chip Conveyors

Chip conveyors come in various designs and types, each suited to specific machining environments. The most common types include

1. Drag Chain Conveyors These use a series of links and chains to move the chips along a predetermined path. They are ideal for moving large volumes of chips and can handle a variety of materials.

2. Auger Conveyors Utilizing a rotating helical screw, auger conveyors transport chips horizontally or at an incline. They are particularly effective for finer chips and swarf, offering a compact design that saves space in the workshop.

3. Magnetic Conveyors These are designed for ferrous materials and utilize magnetic forces to transport metal chips efficiently. They are particularly effective in environments where fine metal particles are generated.

4. Belt Conveyors Simple and versatile, belt conveyors use a continuous loop of material to carry chips away from the machine. They are easy to maintain and can be adapted to various machining setups.

chip conveyor for cnc machine

Benefits of Using Chip Conveyors

The integration of chip conveyors into a CNC machining setup offers several advantages

- Increased Productivity By automating the chip removal process, operators can focus on other critical tasks, leading to increased machine uptime and overall productivity.

- Improved Safety Regularly removing metal chips reduces the risk of accidents and injuries associated with slipping hazards or equipment malfunctions caused by chip accumulation.

- Enhanced Tool Life Removing chips promptly can reduce tool wear and tear, as excessive debris can lead to dulling or damage. This, in turn, lowers the costs associated with tool replacements and maintenance.

- Better Part Quality A cleaner workspace helps maintain machining precision. Unattended chips can interfere with the machining process, potentially leading to defects in the finished product.

- Sustainability Efficient chip removal not only boosts productivity but also makes recycling easier. Many manufacturing operations aim to recycle metal chips, and a conveyor system facilitates the collection and processing of these materials.

Conclusion

As the manufacturing industry continues to evolve, the importance of efficient operations cannot be overstated. Chip conveyors are integral to maintaining a streamlined and productive CNC machining environment. By automating the removal of metal chips and ensuring a clean workspace, these conveyors help manufacturers enhance productivity, maintain product quality, and promote workplace safety. Investing in a quality chip conveyor is key for businesses looking to stay competitive in today’s fast-paced manufacturing landscape.