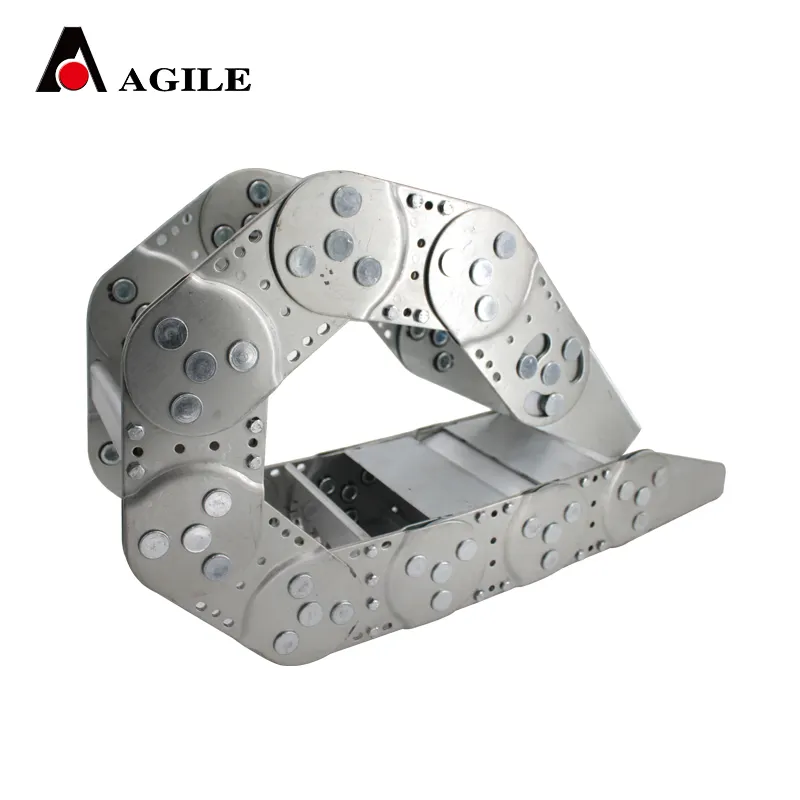

cnc machine used metal swarf chip conveyor

Chip conveyors play a critical role in CNC machine operations, effectively managing and disposing of metal scraps generated during high-precision machining. As a core component facilitating seamless workflow in machining industries, these conveyors significantly enhance productivity, ensure workplace safety, and extend the lifespan of CNC equipment. Understanding their operational excellence from hands-on experience provides unique insights into their contribution to the manufacturing process.

Authoritativeness in chip conveyor application also stems from an appreciation of their role in sustaining CNC machine integrity. By effectively clearing swarf, conveyors prevent chip re-cutting, reducing tool wear and safeguarding surface finishes. This not only prolongs the operational lifespan of machines but maintains high standards of manufacturing quality. Factoring this into production planning bolsters process efficiency, an insight that becomes apparent only with a seasoned understanding of CNC environments. Furthermore, advanced conveyors equipped with coolant management systems offer dual functionality by reclaiming and recycling coolants, an environmentally conscious adaptation enhancing operational sustainability. Trustworthiness in advocating for chip conveyor usage is reinforced by real-world testimonies and third-party endorsements within manufacturing communities. Testimonials from industry leaders reflect the consequential reduction in downtime attributed to efficient chip management systems. The unwavering reliability of these conveyors is a testament to their design prowess, augmented by continuous innovation driven by feedback from frontline CNC operators. Partnerships with reputable conveyor manufacturers further cement the credibility of these recommendations, as they consistently deliver on promises of efficiency and resilience. In summary, the integration of chip conveyors into CNC machine workflows exemplifies precision engineering meeting practical necessity. Their expert design and application drive operational productivity, embody authority in machining strategy, and foster trust through proven performance standards. The nuanced understanding of their functional dynamics emanates from a fusion of technical expertise and on-ground experience, ensuring their indispensable presence in the realm of high-precision machining. As CNC technology advances, the adaptability and efficiency of chip conveyors will undoubtedly continue to steer industrial manufacturing towards ever-greater heights of excellence.

Authoritativeness in chip conveyor application also stems from an appreciation of their role in sustaining CNC machine integrity. By effectively clearing swarf, conveyors prevent chip re-cutting, reducing tool wear and safeguarding surface finishes. This not only prolongs the operational lifespan of machines but maintains high standards of manufacturing quality. Factoring this into production planning bolsters process efficiency, an insight that becomes apparent only with a seasoned understanding of CNC environments. Furthermore, advanced conveyors equipped with coolant management systems offer dual functionality by reclaiming and recycling coolants, an environmentally conscious adaptation enhancing operational sustainability. Trustworthiness in advocating for chip conveyor usage is reinforced by real-world testimonies and third-party endorsements within manufacturing communities. Testimonials from industry leaders reflect the consequential reduction in downtime attributed to efficient chip management systems. The unwavering reliability of these conveyors is a testament to their design prowess, augmented by continuous innovation driven by feedback from frontline CNC operators. Partnerships with reputable conveyor manufacturers further cement the credibility of these recommendations, as they consistently deliver on promises of efficiency and resilience. In summary, the integration of chip conveyors into CNC machine workflows exemplifies precision engineering meeting practical necessity. Their expert design and application drive operational productivity, embody authority in machining strategy, and foster trust through proven performance standards. The nuanced understanding of their functional dynamics emanates from a fusion of technical expertise and on-ground experience, ensuring their indispensable presence in the realm of high-precision machining. As CNC technology advances, the adaptability and efficiency of chip conveyors will undoubtedly continue to steer industrial manufacturing towards ever-greater heights of excellence.