chip conveyor cnc

The Importance of Chip Conveyors in CNC Machinery

In the world of Computer Numerical Control (CNC) machining, efficiency and precision are paramount. One key component that often gets overlooked is the chip conveyor. This device plays a crucial role in maintaining the optimal functioning of CNC machines, directly influencing productivity and the overall quality of the machining process.

What is a Chip Conveyor?

A chip conveyor is a mechanical system designed to remove metal shavings or chips generated during the CNC machining process. These chips can come from various machining operations, such as milling, turning, and drilling. If left unaddressed, the accumulation of chips can lead to several issues, including machine downtime, reduced accuracy, and even damage to the machine itself.

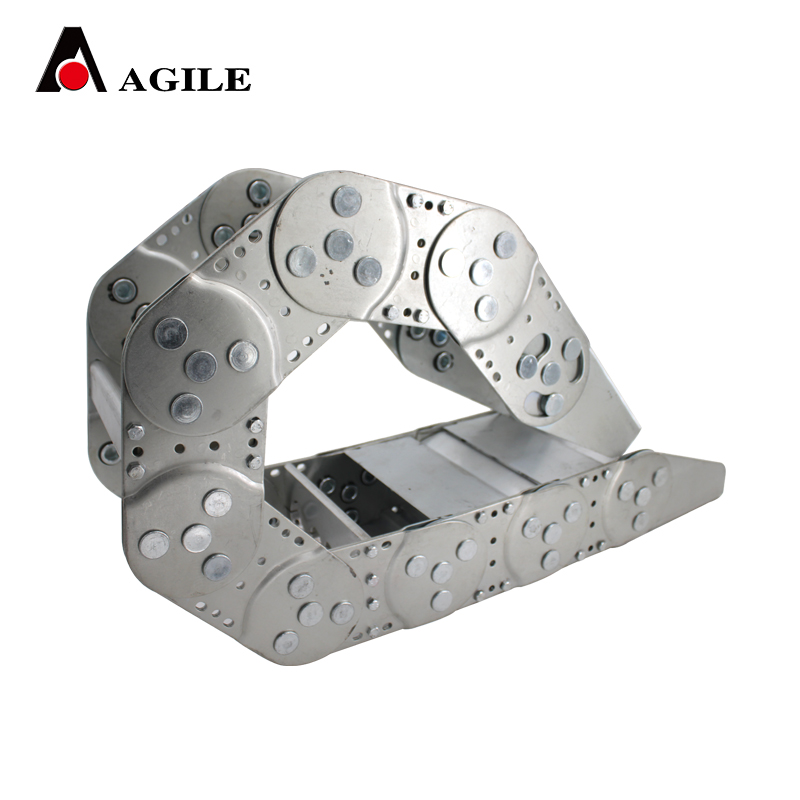

Chip conveyors come in various designs, including belt, paddle, screw, and magnetic systems, each suited for handling different types of materials and chip forms. The choice of conveyor system often depends on the specific requirements of the CNC operation, such as the type of material being machined, the volume of chips produced, and the available space in the workshop.

Benefits of Using Chip Conveyors

1. Improved Efficiency One of the primary benefits of using a chip conveyor is the enhanced efficiency it brings to the CNC machining process. By continuously removing chips from the work area, the conveyor prevents blockages and allows machines to operate at their peak performance. This leads to less downtime, as operators do not need to stop the machine to clear away debris.

chip conveyor cnc

2. Increased Tool Life The presence of chips can affect the cutting tools used in CNC operations. When chips accumulate, they can lead to tool wear and tear, which means tools need to be replaced more frequently. A chip conveyor helps mitigate this issue by keeping the cutting area clear, ensuring that tools remain in optimal condition for longer periods.

3. Better Work Environment A clean working environment is essential not only for productivity but also for safety. Loose chips can create hazards, such as tripping risks or even fires in some cases. By utilizing a chip conveyor, shops can maintain a clean workspace, which reduces the risk of accidents and promotes a safer work environment.

4. Enhanced Machining Accuracy Chip accumulation can affect the accuracy of machining processes. Chips can interfere with the workpiece or the cutting tool, leading to inaccuracies and defects. By effectively removing chips, chip conveyors ensure that the machining process remains precise and high-quality.

5. Reduction of Maintenance Costs Regular maintenance is critical to the longevity of CNC machinery. The build-up of chips can lead to wear on machine components and increased maintenance costs. With a chip conveyor efficiently managing chip disposal, the overall wear and tear on the machine can be significantly reduced, lowering maintenance expenses in the long run.

Conclusion

In conclusion, chip conveyors are essential components of CNC machinery that offer numerous benefits. From improving operational efficiency and extending tool life to promoting safety and enhancing machining accuracy, the importance of chip conveyors cannot be overstated. As CNC technology continues to advance, the incorporation of efficient chip removal systems will play a vital role in ensuring that machining operations can keep pace with growing demands. For businesses seeking to optimize their production processes, investing in a reliable chip conveyor system is undoubtedly a wise decision that can lead to increased productivity and profitability.

As the manufacturing industry continues to evolve, chip conveyors will remain an integral part of maintaining the effectiveness and reliability of CNC machines, paving the way for a cleaner, safer, and more efficient future in machining.