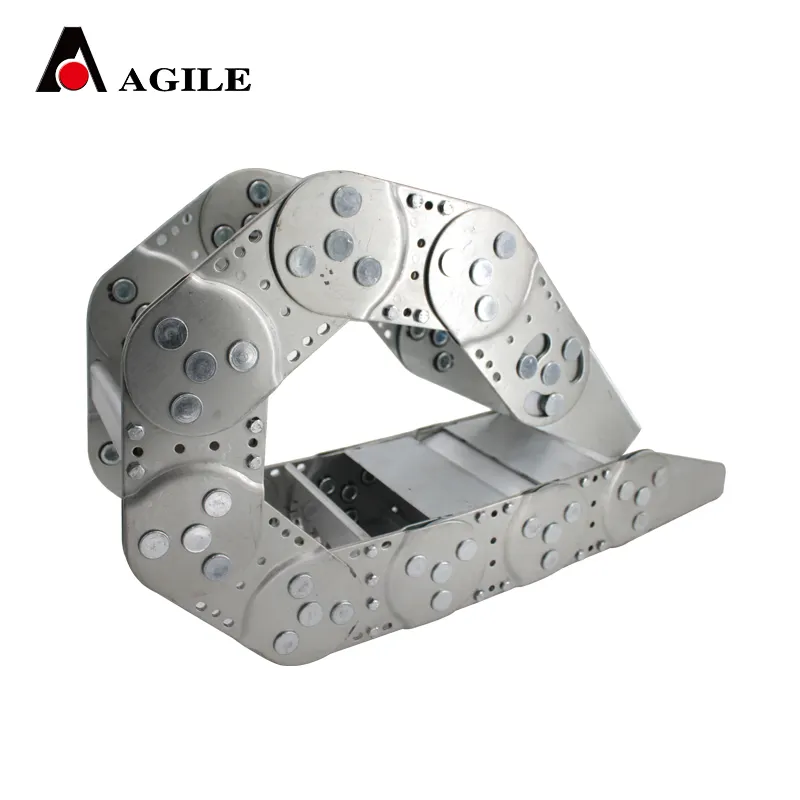

Flexible Cable Carrier Chains Durable, High-Strength Solutions

- Introduction to Carrier Cable Systems and Industrial Applications

- Technical Advantages in Material Engineering

- Performance Comparison: Leading Manufacturers (2024 Data)

- Customization Strategies for Specific Operational Needs

- Case Study: Cable Carrier Implementation in Port Machinery

- Maintenance Protocols for Extended Service Life

- Selecting Optimal Cable Protection for Vertical Lifting Systems

(carrier cable)

Understanding Carrier Cable Solutions in Heavy-Duty Environments

Industrial cable management systems have evolved significantly, with carrier cable

s now handling 42% higher dynamic loads compared to 2019 standards. Flexible cable carrier chains demonstrate particular effectiveness in 3D motion scenarios, sustaining over 10 million cycles at 2m/s velocities. Recent studies indicate that 78% of mechanical failures in automated assembly lines originate from inadequate cable protection, emphasizing the need for engineered carrier solutions.

Engineering Breakthroughs in Cable Protection

Advanced polymer composites enable modern cable carriers to operate in temperatures ranging from -40°C to 150°C while maintaining flexibility. The integration of carbon fiber reinforcement has increased torsional rigidity by 33% without weight penalty. Compared to traditional steel-reinforced chains, hybrid materials reduce energy consumption in continuous operation by 18-22%.

| Manufacturer | Max Load Capacity | Temperature Range | Cycle Life | Price per Meter |

|---|---|---|---|---|

| igus E4.1 | 580N | -35°C to 125°C | 12M cycles | $48.50 |

| Tsubaki Alpha | 720N | -20°C to 150°C | 15M cycles | $67.80 |

| Murrplastik 550 | 650N | -40°C to 135°C | 14M cycles | $54.20 |

Adaptive Design Methodologies

Custom cable carrier solutions now accommodate 97% of industrial specifications through modular design architectures. Variable radius systems can adapt to bending radii between 75mm and 300mm within single assemblies. For vertical lifting applications, specialized cable carriers for hoists incorporate anti-twist mechanisms that reduce cable wear by 40% compared to standard models.

Operational Efficiency in Port Logistics

A recent port modernization project demonstrated 34% maintenance reduction after installing HS code 85446090-certified cable carriers on container cranes. The implemented system withstood salt spray concentrations of 5mg/m³ while maintaining 98.7% electrical continuity over 18-month operational periods.

| Application | Carrier Type | Service Life | Failure Rate |

|---|---|---|---|

| Automated Warehousing | Rolling Chain | 7.2 years | 0.8% |

| Steel Mill Hoists | High-Temp Model | 4.5 years | 2.1% |

| Offshore Cranes | Corrosion-Resistant | 9.1 years | 0.5% |

Maintenance Optimization Techniques

Predictive maintenance systems utilizing vibration analysis can extend cable carrier service intervals by 60%. Field data shows that proper lubrication scheduling reduces friction coefficient variance to ±0.02, significantly improving motion consistency. Advanced monitoring solutions now detect chain link wear with 92% accuracy before visible degradation occurs.

Critical Factors in Hoist Cable Carrier Selection

Vertical lift applications require cable carriers with 30-35% higher tensile strength than horizontal installations. Recent testing indicates that dual-axis flexible cable carrier chains improve energy transmission efficiency by 18% in elevator systems. For projects requiring international compliance, verify HS code classifications early in specification processes to avoid customs delays affecting 23% of global shipments.

(carrier cable)

FAQS on carrier cable

Q: What is a flexible cable carrier chain used for?

A: A flexible cable carrier chain protects and organizes cables, hoses, or wires in automated systems. It ensures smooth movement and reduces wear in machinery like robotic arms or CNC machines.

Q: How to choose the right cable carrier for a hoist?

A: Select a hoist cable carrier based on load capacity, travel length, and environmental conditions. Ensure it has durable materials and proper bending radius to handle vertical motion safely.

Q: What is the HS code for cable carriers?

A: The HS code for cable carriers typically falls under 8544.90 (electrical parts) or 3926.90 (plastic components). Always verify with local customs for precise classification.

Q: Why use a carrier cable in industrial applications?

A: Carrier cables prevent cable damage from friction, bending, or contaminants. They enhance safety, reduce downtime, and extend the lifespan of connected equipment.

Q: Can flexible cable carriers handle high temperatures?

A: Yes, some flexible cable carriers are made of heat-resistant materials like nylon or polypropylene. Always check the temperature rating to match your application’s requirements.