cable track system

Understanding Cable Track Systems Essential for Modern Industries

In today’s fast-paced industrial environment, efficiency and safety have become paramount. One of the pivotal innovations that serve these requirements is the cable track system. These systems are designed to manage and protect cables in various applications, ranging from manufacturing facilities to construction sites and automation systems.

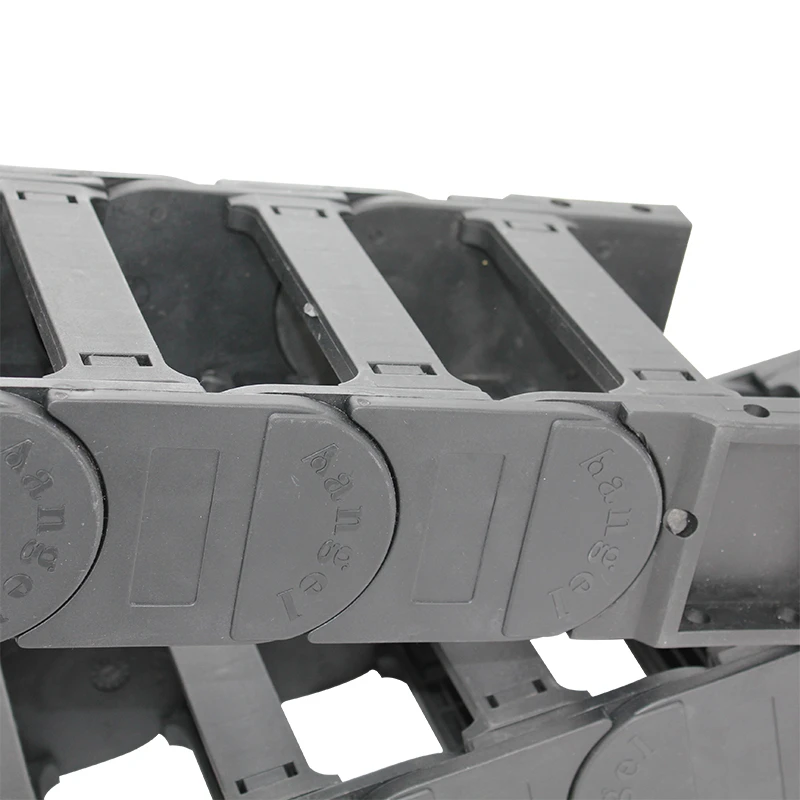

A cable track system, often referred to as a drag chain or energy chain, is a flexible structure that organizes, guides, and protects movable cables and hoses. The need for such systems arises from the challenges posed by traditional cable management methods, which can lead to cable wear, tangling, and potential safety hazards. The design of cable track systems addresses these issues, ensuring that cables operate smoothly and efficiently in dynamic environments.

Components of Cable Track Systems

A standard cable track system comprises several key components. The primary element is the drag chain, typically made from durable materials like plastics or metals, which allows it to withstand the rigors of constant movement. Inside the chain, various cables, wires, and hoses are laid out, ensuring they are kept organized and separated. Additional components include mounting brackets, which attach the chain to a stationary structure, and connectors that secure the cables at both ends.

Applications of Cable Track Systems

Cable track systems are versatile and find applications across multiple sectors. In manufacturing, these systems are essential in assembly lines where robotic arms need to move freely and flexibly. Without a proper cable track system, cables would quickly become entangled, leading to downtime and costly disruptions.

In the field of automation and robotics, cable track systems play a critical role as well. Automated machinery often requires intricate networks of cables that need to move with precision. These systems safeguard the cables from mechanical wear and tear, ultimately enhancing the longevity of the equipment.

cable track system

Construction sites also benefit greatly from cable track systems. Heavy machinery and equipment typically require numerous cables for operations, and using cable tracks helps ensure these cables remain protected from harsh elements, wear, or accidental disconnections. This not only improves safety on-site but also enhances operational efficiency.

Benefits of Using Cable Track Systems

The adoption of cable track systems provides numerous benefits. Firstly, they help maintain order and organization in environments that involve multiple cables. By properly guiding and managing cables, these systems reduce the likelihood of accidents and equipment failures caused by tangled wires or broken connections.

Secondly, cable track systems promote equipment longevity. By preventing cable abrasion and minimizing movement-induced stress, these systems extend the lifespan of both cables and machinery, leading to substantial cost savings in maintenance and replacements.

Moreover, cable track systems enhance safety by eliminating trip hazards created by loose cables and preventing incidental damage from machinery operations. This is crucial not only in workplaces but also in public areas where equipment operates near pedestrians.

Conclusion

Cable track systems are an indispensable solution for modern industries looking to enhance operational efficiency, safety, and equipment longevity. With their ability to organize, protect, and manage cables, these systems provide a reliable framework essential for a multitude of applications. As industries evolve towards more automated and complex operations, the role of cable track systems will undoubtedly become even more critical in shaping the future of industrial efficiency and safety.