Flexible cable management solutions for efficient track systems and chain organization

The Importance of Cable Track Chains in Modern Machinery

In the realm of modern machinery and industrial applications, the significance of cable track chains cannot be overstated. These components, often referred to as cable carriers, play an essential role in the safe and efficient movement of cables, hoses, and other vital connections in various systems. Their design and functionality greatly influence equipment longevity, performance, and maintenance, making them a critical element in various industries.

Understanding Cable Track Chains

Cable track chains are specialized structures designed to guide and protect cables and hoses in machinery, particularly in automated systems, robotics, and mobile equipment. They provide a controlled pathway for these cables, preventing tangling, wear, and damage. Constructed from durable materials such as plastic or metal, these track chains can withstand harsh environmental conditions, high temperatures, and heavy loads, ensuring reliability in various applications.

Applications Across Industries

The applications of cable track chains span a wide range of industries, each benefiting from their unique properties. In the manufacturing sector, for instance, they are commonly found in CNC machines, conveyor systems, and robotic arms, facilitating the seamless operation of complex machinery. Their ability to accommodate movement—whether linear or orbital—ensures that cables remain organized and free from entanglements during operation.

In the construction industry, cable track chains are integral to heavy machinery such as excavators and cranes. These machines often operate in challenging environments, where cables are subjected to stress, abrasion, and exposure to the elements. By utilizing cable track chains, manufacturers can enhance the durability of their equipment, significantly reducing downtime and maintenance costs due to cable damage.

Moreover, in the entertainment industry, cable track chains are vital for stage rigging and automated lighting systems. The ability to guide and secure power and control lines allows for intricate setups that can be adjusted with precision, enhancing the overall production experience.

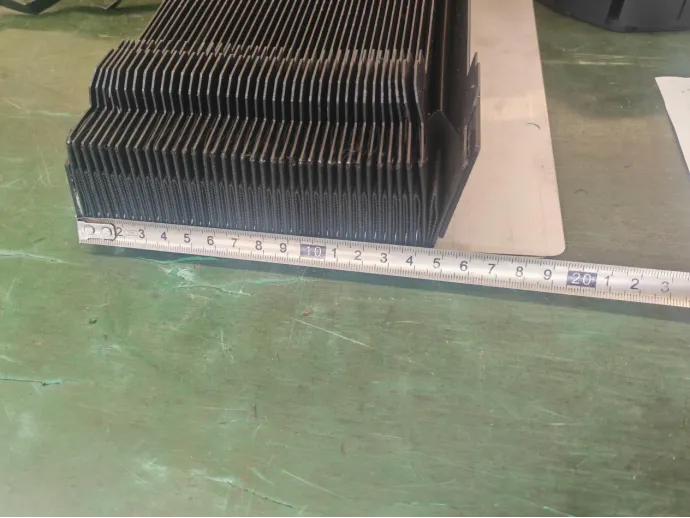

cable track chain

Design Considerations

When choosing a cable track chain, several design considerations must be taken into account. The size and geometry of the tracks must correspond with the dimensions of the cables and hoses they will carry. Additionally, the flexibility and bend radius of the track chain are crucial for applications requiring dynamic movement. For instance, a smaller bend radius may be necessary for compact machines, while larger machines may benefit from tracks designed for greater distances and heavier loads.

The material composition is another important factor. While plastic tracks offer lightweight solutions with good resistance to chemical exposure, metal tracks provide additional strength and are suitable for applications involving heavier payloads or extreme conditions.

Maintenance and Longevity

One of the key benefits of using cable track chains is the reduction in maintenance efforts. By keeping cables organized and protected, these chains help prevent wear and tear that can lead to costly repairs or replacement. Regular inspection and cleaning of the track chains can further extend their lifespan, ensuring consistent performance over time.

Proper installation is also critical for efficiency. Incorrect installation can result in unnecessary strain on cables and hoses, leading to premature failure. Therefore, it is essential to follow manufacturer guidelines and industry standards during installation to guarantee the long-term efficacy of the cable track system.

Conclusion

In conclusion, cable track chains are indispensable components in the machinery and industrial sectors. Their ability to organize and protect cables enhances operational efficiency, reduces maintenance costs, and prolongs the life of equipment. As industries continue to evolve, the role of cable track chains will undoubtedly expand, reflecting advancements in technology and the increasing complexity of machinery. Manufacturers that prioritize the implementation of effective cable management systems, including track chains, will position themselves for success in an increasingly competitive landscape. With these systems in place, businesses can optimize performance, ensure safety, and achieve greater reliability in their operations.