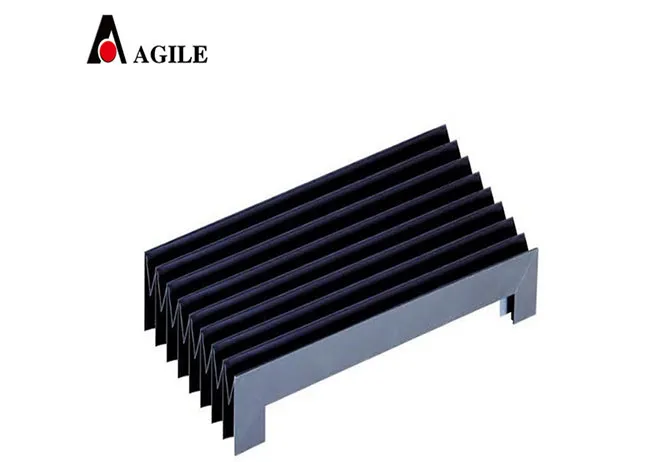

cable track

Navigating the maze of modern industrial design, cable tracks have emerged as an indispensable component, ensuring the seamless operation of machinery by managing and protecting cables and hoses. With years of experience in the field of industrial automation, I have witnessed firsthand the transformative impact of intelligently chosen cable tracks on productivity and machine longevity.

Trustworthiness in the cable track industry is often measured by the predictive maintenance solutions that clients implement. Utilizing smart technology like IoT-enabled sensors can transform the humble cable track into a high-tech sentinel safeguarding against operational disruptions. These sensors monitor the health of the cables in real-time, providing warnings for potential issues before they escalate into costly repairs or replacements. Success stories from industry leaders underscore the benefits of adopting quality cable tracks. For example, a leading automotive manufacturer optimized its assembly line operations by upgrading to a more resilient, corrosion-resistant cable track system. This change not only reduced maintenance downtime by 30% but also enhanced worker safety by eliminating tripping hazards. This tangible shift in performance underscores the critical value of investing wisely in cable management solutions. Cable tracks, though often overlooked, are vital components that play a significant role in the efficiency and safety of complex machinery operations. By combining practical experience with cutting-edge innovation, professionals in this sector can significantly enhance operational efficiency, extend machine lifespans, and mitigate risks. Ultimately, the judicious selection and application of cable tracks reflect a commitment to excellence and reliability, providing a solid foundation for future technological advancements in any industrial setting.

Trustworthiness in the cable track industry is often measured by the predictive maintenance solutions that clients implement. Utilizing smart technology like IoT-enabled sensors can transform the humble cable track into a high-tech sentinel safeguarding against operational disruptions. These sensors monitor the health of the cables in real-time, providing warnings for potential issues before they escalate into costly repairs or replacements. Success stories from industry leaders underscore the benefits of adopting quality cable tracks. For example, a leading automotive manufacturer optimized its assembly line operations by upgrading to a more resilient, corrosion-resistant cable track system. This change not only reduced maintenance downtime by 30% but also enhanced worker safety by eliminating tripping hazards. This tangible shift in performance underscores the critical value of investing wisely in cable management solutions. Cable tracks, though often overlooked, are vital components that play a significant role in the efficiency and safety of complex machinery operations. By combining practical experience with cutting-edge innovation, professionals in this sector can significantly enhance operational efficiency, extend machine lifespans, and mitigate risks. Ultimately, the judicious selection and application of cable tracks reflect a commitment to excellence and reliability, providing a solid foundation for future technological advancements in any industrial setting.