Benefits of Using Cable Split Loom for Organized Wiring Solutions

The Importance of Cable Split Loom in Modern Wiring Solutions

In today’s fast-paced technological world, the management of wires and cables is more critical than ever. As industries push for efficiency and safety, the need for effective cable organization and protection has grown exponentially. One key component that has emerged to address these requirements is the use of cable split loom. Often overlooked, this simple yet innovative product plays a vital role in the realm of electrical wiring and cable management.

What is Cable Split Loom?

Cable split loom is a tubing made from high-density polyethylene (HDPE) or similar materials. It is designed to encase multiple cables and wires, providing both physical protection and organization. The split design allows for easy insertion and removal of cables, making it an efficient solution for dynamic wiring setups. Typically available in various sizes and lengths, cable split loom can accommodate different cable diameters, ensuring versatility across various applications.

Functions and Benefits

1. Protection Against Environmental Factors One of the primary advantages of using cable split loom is its ability to safeguard wires from environmental hazards such as moisture, dust, and chemicals. In industrial settings, where cables might be exposed to liquids or harsh conditions, split loom material acts as a barrier, prolonging the life of the wiring.

2. Physical Damage Prevention Cables are often susceptible to wear and tear due to abrasion, cuts, or impact. By enclosing them in a split loom, the risk of physical damage is substantially reduced. This is particularly important in areas with heavy machinery, where wires are at a higher risk of being snagged or crushed.

3. Organized Wiring Cable split loom helps in organizing multiple wires, preventing tangling and confusion. In complex installations, such as in automotive wiring or large electronic systems, using split loom ensures that cables are neatly arranged and easily identifiable. This organization not only makes maintenance easier but also enhances the overall aesthetic of the wiring system.

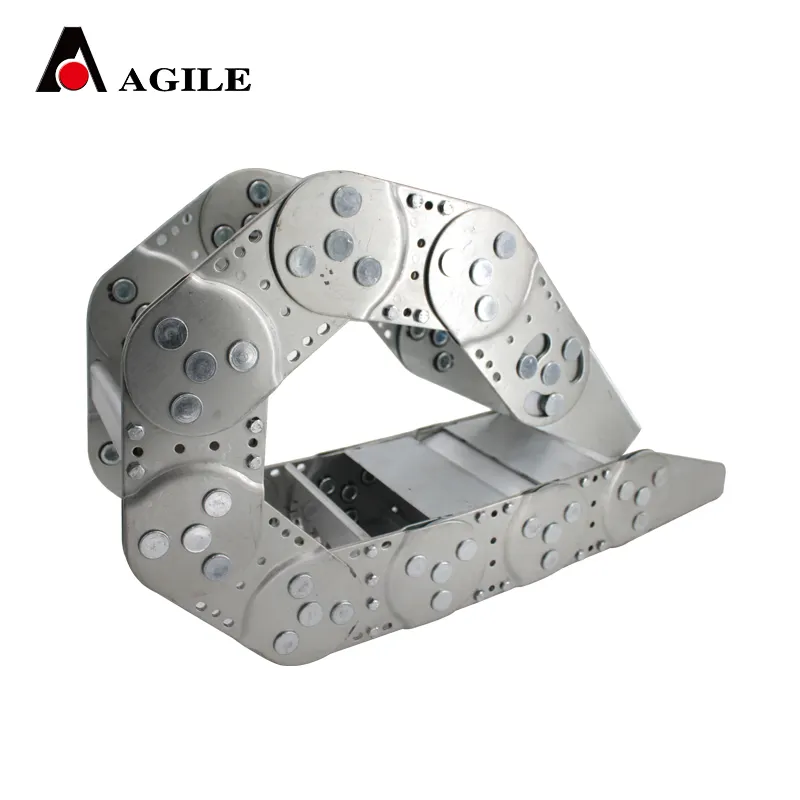

cable split loom

4. Heat Resistance Many types of cable split loom offer excellent heat resistance. This characteristic is crucial in applications where wires may experience high temperatures, as it helps maintain the integrity of the insulation and overall functionality of the electrical system.

5. Easy Installation The split design of the loom allows for quick and hassle-free installation. Electricians and technicians can easily slide wires into the loom and remove them as necessary without the need for complex tools or processes. This feature saves valuable time during installations and repairs.

Applications of Cable Split Loom

Cable split loom is utilized across a variety of sectors, including automotive, aerospace, manufacturing, and home improvement. In automotive applications, for instance, it protects the vast number of wires that run through vehicles, shielding them from the harsh environments they encounter on the road. In manufacturing, machinery that requires extensive wiring often relies on split loom to maintain organization and safety in busy workshop settings.

Conclusion

As we become increasingly reliant on technology in our daily lives and industries, the importance of proper cable management cannot be overstated. Cable split loom offers a proactive solution to the challenges posed by disorganized and exposed wiring. With its protective properties, organizational benefits, and ease of use, split loom can contribute significantly to the efficiency and safety of wiring systems.

In summary, whether in an automotive application, industrial setting, or home project, investing in cable split loom can enhance the longevity of electrical systems while promoting safety. As technology continues to evolve, adopting effective cable management solutions like cable split loom will be paramount in ensuring seamless operations across various domains.