Exploring Cable and Hose Management Solutions for Efficient Industrial Operations

Understanding Cable and Hose Carriers Essential Components for Modern Machinery

In the world of industrial machinery and equipment, the efficient management of cables and hoses is crucial for ensuring smooth operations. Among the key solutions for this purpose are cable and hose carriers, also known as drag chains or energy chains. These systems are designed to protect, guide, and organize cables and hoses, preventing wear and tear caused by constant movement and mechanical stress. This article explores the various types of cable and hose carriers, their applications, benefits, and considerations for choosing the right solution for specific needs.

What are Cable and Hose Carriers?

Cable and hose carriers are essentially protective systems that support and manage the movement of cables and hoses in machinery. They come in various styles, including open and closed designs, and can be manufactured from a variety of materials such as plastic, steel, and aluminum. The primary purpose of these carriers is to prevent tangling, avoid abrasion, and reduce stress on the cables and hoses as they traverse along with mechanical components.

Applications of Cable and Hose Carriers

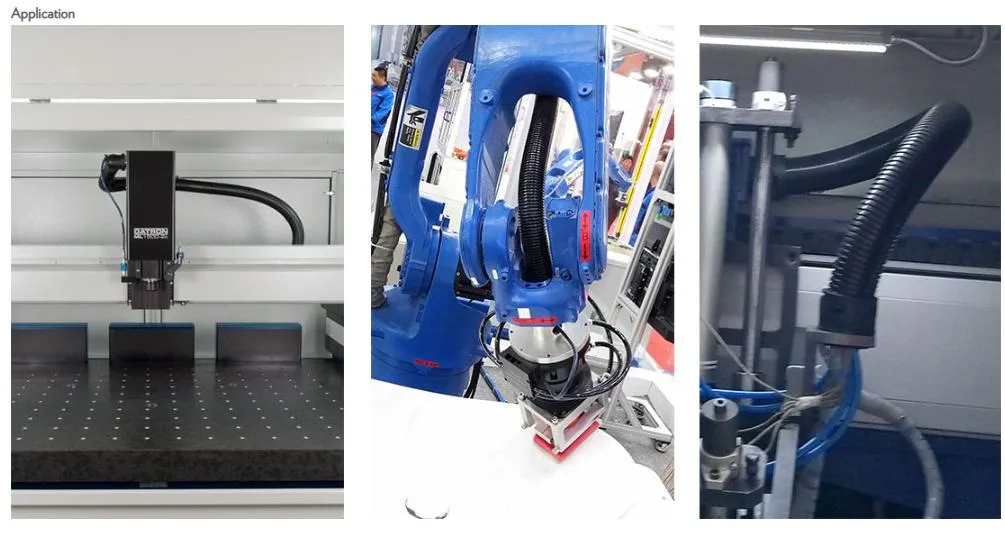

These carriers are widely used across various industries, including manufacturing, automotive, robotics, and aerospace. They are particularly beneficial in applications involving moving machinery where flexibility and mobility are essential. For instance, in automated assembly lines, robotic arms require a complex network of electrical cables and pneumatic hoses to operate effectively. Here, cable and hose carriers play a vital role in maintaining organization and preventing damage to these critical components.

Moreover, cable and hose carriers are increasingly utilized in construction machinery, such as cranes and excavators, where the components are subject to extreme motion and environmental conditions. In these situations, the carriers not only protect the cables and hoses but also improve the overall safety and reliability of the machinery.

Benefits of Using Cable and Hose Carriers

The implementation of cable and hose carriers comes with a myriad of advantages. First and foremost, they significantly enhance the lifespan of cables and hoses by minimizing wear caused by friction and movement. With reduced downtime and maintenance requirements, businesses can realize considerable cost savings.

cable & hose carriers

Additionally, these carriers improve safety in the workplace. By neatly organizing cables and hoses, they help prevent tripping hazards and reduce the likelihood of accidents caused by tangled cables. This organized setup also facilitates easier troubleshooting and repairs, as everything is easily accessible and identifiable.

Another critical benefit is the enhancement of performance. By providing a structured path for cables and hoses, drag chains contribute to smoother operations, allowing machines to operate at optimal efficiency. This is particularly important in high-speed applications where any lag can lead to productivity losses.

Choosing the Right Cable and Hose Carrier

When selecting a cable and hose carrier, several factors must be considered. First, the application requirements, such as the type of movement (linear or rotary), the range of motion, and the environmental conditions, play a crucial role in determining the suitable design and material of the carrier.

Furthermore, the carrier's size and space constraints must be evaluated. Adequate room must be considered for the cables and hoses to ensure they can bend and move without being pinched or damaged. Additionally, the expected load bearing capacity should align with the operational demands of the machinery.

Lastly, it’s essential to account for compatibility with existing machinery. Manufacturers often provide customization options to ensure that the cable and hose carriers can fit seamlessly into various setups, further enhancing the overall efficiency and performance of the systems.

Conclusion

In conclusion, cable and hose carriers represent a vital component of modern machinery, ensuring the protection, organization, and efficient management of cables and hoses. Their application across various industries underscores their importance in improving cable lifespan, enhancing workplace safety, and optimizing machine performance. By carefully selecting the appropriate carrier for specific needs, companies can enhance their operational efficiencies and contribute to safer work environments. As technology continues to evolve, the role of these carriers will likely expand, driving further innovations in machinery design and functionality.