Flexible Cable Management Solutions for Efficient Hose Carrier Systems

Understanding Cable Hose Carriers Essential Components for Modern Machinery

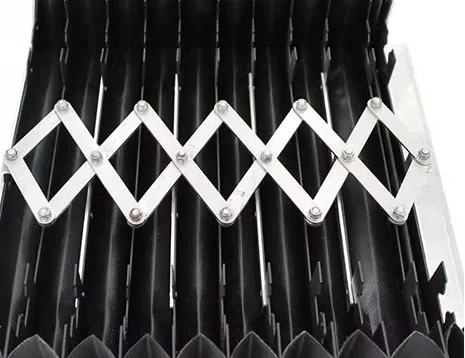

In today’s fast-paced industrial environment, where efficiency and safety are paramount, cable hose carriers have emerged as essential components in the operation of various machinery. Also known as cable chains, drag chains, or energy chains, these innovative systems provide a reliable solution for managing cables and hoses that supply power, data, and fluids to moving parts of equipment.

What are Cable Hose Carriers?

Cable hose carriers are mechanical structures designed to guide and protect flexible hoses and electrical cables. They allow for smooth movement while preventing tangling and wear during operation. Typically made from materials such as plastic, steel, or aluminum, these carriers come in various sizes and configurations to accommodate different applications, from light-duty tasks to heavy industrial machinery.

Benefits of Using Cable Hose Carriers

1. Improved Safety By enclosing and managing cables and hoses, cable hose carriers reduce the risk of tripping hazards in work environments. They keep cables organized and off the ground, minimizing the chances of accidents.

2. Enhanced Durability These carriers are designed to withstand the rigors of motion and environmental factors such as heat, chemicals, and abrasion. By protecting cables and hoses from external damage, they prolong the lifespan of these components.

3. Increased Flexibility Cable hose carriers allow for free movement in multiple directions. They can be used in various applications, including robotics, conveyor systems, and automated machinery, where dynamic movement is essential.

4. Reduced Maintenance With cables and hoses securely housed within a carrier, the need for constant inspection and maintenance is decreased. This not only saves time but also reduces operational costs over time.

Applications of Cable Hose Carriers

cable hose carrier

Cable hose carriers are utilized across a wide spectrum of industries. In manufacturing plants, they are frequently seen in assembly lines where robotic arms need unrestricted movement while powered. In the aerospace and automotive sectors, these carriers ensure that critical systems are seamlessly connected even during high-speed operations. Other applications include but are not limited to, material handling systems, CNC machines, and even entertainment technology, such as stage equipment that requires intricate cable management.

Choosing the Right Cable Hose Carrier

When selecting a cable hose carrier, several factors should be considered

1. Load Capacity Understand the weight of the cables and hoses that need to be managed. Ensuring the carrier can handle the load is critical for its effective operation.

2. Travel Distance Evaluate the distance the carrier will need to travel. This will influence the size and length of the carrier required.

3. Environmental Conditions Consider factors such as exposure to chemicals, moisture, or extreme temperatures that may affect the material choice of the carrier.

4. Bending Radius It’s vital to select a carrier that offers a suitable bending radius to prevent damage to cables and hoses during movement.

Conclusion

Cable hose carriers are indispensable in modern mechanics and automation, providing safe, efficient, and reliable management of cables and hoses in a myriad of applications. As industries continue to advance, the role of cable hose carriers will become increasingly vital, helping ensure both safety and efficiency in the workplace. By understanding their importance and how to choose the right ones, businesses can enhance their productivity while safeguarding their valuable equipment and personnel.