cable drag chain size chart

Understanding Cable Drag Chain Size Charts

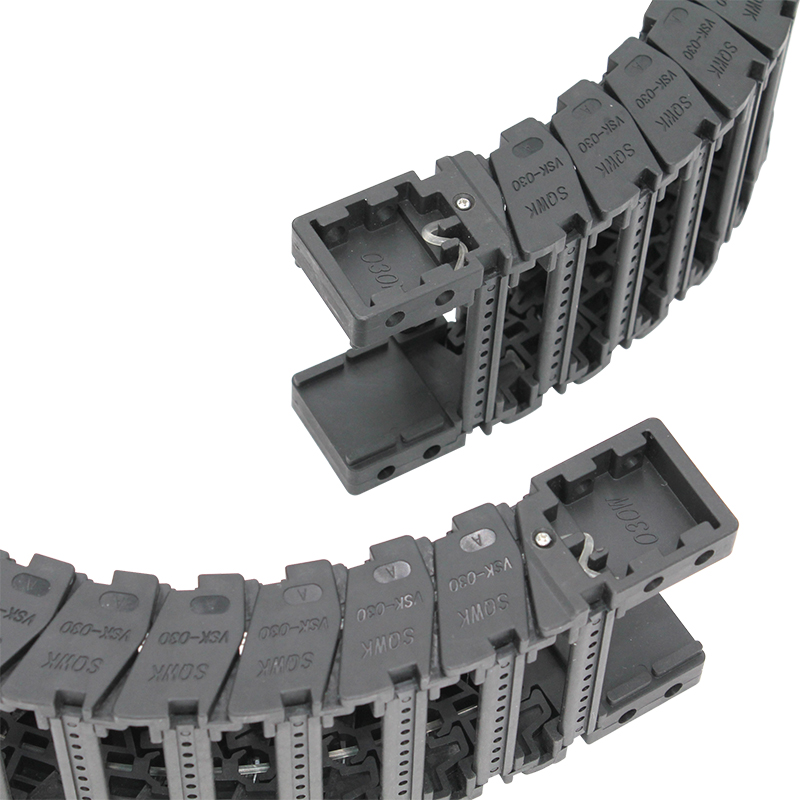

In the world of industrial automation and robotics, cable management is a critical aspect that ensures smooth operation and longevity of machinery. One essential component in this domain is the cable drag chain. These chains organize and protect electrical cables and hoses as they move alongside robotic arms, conveyors, and moving parts in machinery. Choosing the right size of cable drag chain is crucial for optimum performance, and this is where cable drag chain size charts come into play.

What is a Cable Drag Chain?

A cable drag chain, also known as a cable carrier, is designed to guide and protect flexible cables, hoses, and tubing. The drag chains allow for continuous bending, ensuring that cables remain undamaged during movement. They come in various shapes, sizes, and materials, catering to a wide array of applications across different industries.

Importance of Sizing

Correctly sizing a cable drag chain is vital for several reasons. Firstly, an inadequately sized chain can lead to cable wear and tear, resulting in frequent maintenance, downtime, and ultimately, increased operational costs. A chain that is too large may be cumbersome and may not support the cables effectively, while one that is too small may lead to pinching or kinking, compromising the integrity of the cables.

Interpreting Cable Drag Chain Size Charts

Cable drag chain size charts are valuable tools that simplify the selection process. These charts typically feature a range of chain sizes, complete with specifications such as width, height, and bend radius. Here are some key factors to consider when using these charts

1. Inner Height and Width This dimension determines how many and what type of cables can fit within the chain. It is crucial to account for both the diameter of the cables and any necessary space for movement and flexibility.

2. Bend Radius The bend radius is the minimum radius that the cable drag chain can achieve during flexing. This is important in applications where space is limited, as a smaller bend radius may be required. Choosing a chain with an adequate bend radius will not only prevent damage but also maintain performance levels.

cable drag chain size chart

3. Load Capacity Different drag chains have varying load capacities, which is determined by the materials used and the design of the chain. It's essential to choose a chain that can withstand the weight of the cables and hoses it will carry.

4. Chain Length The length of the chain should correspond to the range of movement of the machinery. Proper sizing will ensure that the drag chain can accommodate both the full extension and retraction of the cables.

5. Material Composition Depending on the application, the material of the drag chain can vary. For example, chains may be made of plastic, steel, or other materials that can resist environmental factors such as chemicals, extreme temperatures, or UV exposure.

Practical Steps for Sizing Your Drag Chain

To make the right choice, follow these steps

- Assess your Cables Begin by determining the total number of cables/hoses and their sizes (diameter and length). This will help you approximate the necessary cross-sectional area for your drag chain. - Check the Movement Range Analyze the movement paths in your machinery to define the bending and extension requirements.

- Utilize Size Charts Refer to the cable drag chain size chart to select appropriate sizes based on your calculated dimensions.

- Consult Experts if Needed If you're uncertain, do not hesitate to consult manufacturers or experts in industrial cable management systems.

Conclusion

Selecting the right cable drag chain is essential for the efficiency and longevity of any automated system. By utilizing cable drag chain size charts, you ensure that your installation capitalizes on effective cable management practices, minimizing the risk of wear and tear. Remember, investing time in the right selection now can save significant costs and headaches in the future, allowing for streamlined operations and reduced maintenance hassles. With careful evaluation and proper sizing, your machinery will operate smoothly, productively, and reliably for years to come.