Understanding Cable Chain Drag and Its Impact on Mechanical Systems

Understanding Cable Chain Drag Enhancing Efficiency and Safety in Machinery

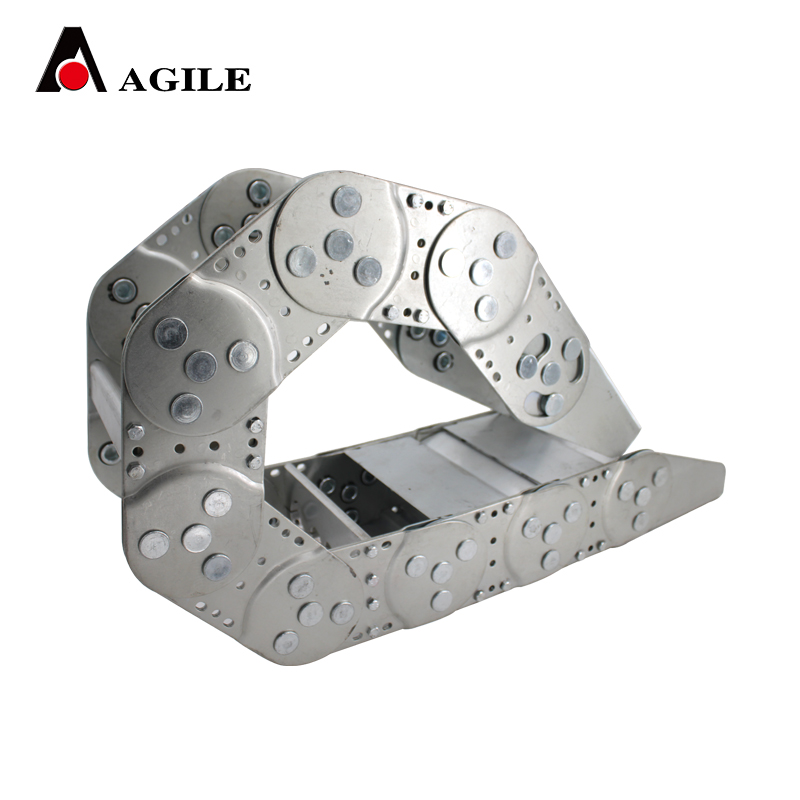

In industrial settings, the efficient management of cables and wires is crucial for maintaining smooth operations and ensuring safety. One component that has gained prominence in this context is the cable chain, specifically designed to protect and manage flexible cables and hoses. However, the phenomenon of cable chain drag is an important consideration for operators and engineers seeking to optimize machinery performance.

What is Cable Chain Drag?

Cable chain drag refers to the resistance encountered by a cable chain as it moves along its designated path. This can occur due to various factors, including the weight of the cables housed within the chain, the friction between the chain and its guiding tracks, and the angle of movement. In practical terms, drag can lead to increased wear and tear on both the cables and the machinery, potentially resulting in equipment failure or downtime.

Understanding the mechanics of cable chain drag is essential for designing systems that minimize friction and maximize efficiency. Manufacturers are increasingly focusing on reducing drag through innovative designs that facilitate smoother movements, which can significantly extend the lifespan of both the cables and the machinery they connect.

Factors Contributing to Cable Chain Drag

1. Weight of Cables The heavier the cables within the chain, the more drag is experienced. This is particularly relevant in applications where multiple or bulky cables are used. Selecting lighter, yet sturdy cables can help alleviate drag.

2. Material of the Chain The type of material used to manufacture the cable chain can also impact drag. Chains made from high-quality, low-friction materials can reduce resistance, making movements more efficient.

3. Design and Length of the Chain Longer chains typically have more components that can contribute to drag, thus careful design consideration must be given to length and configuration to maintain efficiency.

4. Environmental Factors External factors such as temperature, dust, and humidity can affect the performance of both the cable chain and the cables themselves. For instance, increased dust accumulation can lead to higher friction, thereby increasing drag.

cable chain drag

5. Motion Dynamics The speed and direction of movement play a significant role in drag. Rapid changes in speed or direction can increase resistance, so planning for smooth acceleration and deceleration is vital.

Strategies to Minimize Cable Chain Drag

1. Optimized Cable Selection Choosing the appropriate cables that are lighter in weight yet robust enough to handle the required power can significantly reduce drag.

2. Regular Maintenance Routine inspections and maintenance of both the cables and the cable chain can mitigate the accumulation of dirt and friction, helping to maintain optimal performance.

3. Adaptive Design Solutions Using advanced cable chain designs, such as those with tapered or rounded edges, can reduce contact resistance as the chain navigates corners and curves.

4. Incorporating Lubrication Applying suitable lubricants can help in reducing friction between moving parts, which is an effective way to combat cable chain drag.

5. Utilizing Energy-Efficient Drives Implementing machinery that includes energy-efficient drives can reduce the overall load on cable chains, effectively decreasing cable drag.

Conclusion

In conclusion, understanding and managing cable chain drag is essential for enhancing the efficiency and longevity of machinery in industrial environments. By focusing on strategic cable selection, regular maintenance, and innovative design solutions, operators can minimize drag effectively. This not only contributes to the overall safety and functionality of machinery but also enhances productivity and reduces operational costs. As industries continue to evolve and adopt more advanced technologies, the importance of effectively managing cable chains and their associated drag will remain a critical focus area.