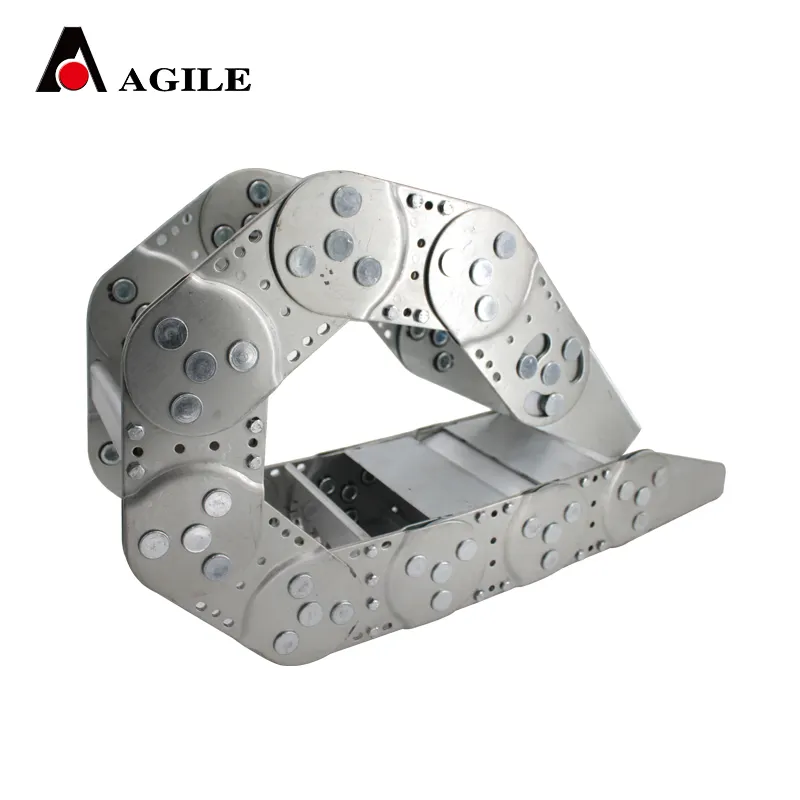

cable chain cnc

Understanding Cable Chains in CNC Applications

In the world of CNC (Computer Numerical Control) machining, efficiency, precision, and reliability are paramount. One of the unsung heroes that contribute significantly to these factors is the cable chain, also known as drag chain or energy chain. This innovative component plays a vital role in organizing and protecting cables and hoses within CNC machines, ensuring smooth and uninterrupted operation.

What is a Cable Chain?

A cable chain is a system designed to guide and contain cables and other flexible components such as hoses. It comprises a series of interconnected links that form a flexible, modular chain. This configuration allows the chain to bend and flex while maintaining the integrity and safety of the cables it houses. The primary purpose of a cable chain in CNC applications is to facilitate the movement of cables as the machine operates, preventing tangling, wear, and damage.

Importance of Cable Chains in CNC Machining

1. Protection of Cables During CNC operations, the movement of parts can subject cables to wear and tear, resulting in potential failures and downtime. Cable chains protect these cables by keeping them organized and shielded from physical damage.

2. Improved Efficiency Cable chains enhance the operational efficiency of CNC machines. By ensuring that cables and hoses are neatly contained and untangled, they facilitate smooth motion and reduce friction, allowing for faster operation and productivity.

3. Flexibility and Range of Motion CNC machines often have complex movements, including linear and rotary motions. Cable chains are designed to accommodate these various movements, ensuring that the cables can extend and retract without restriction. This flexibility is crucial in advanced CNC systems that require precision and versatility.

4. Ease of Maintenance A well-organized cable chain system simplifies maintenance and troubleshooting. When cables are clearly arranged, identifying faults or replacing damaged components becomes more manageable, reducing downtime and repair costs.

cable chain cnc

5. Customization and Versatility Cable chains come in various sizes and configurations to suit different machine types and applications. This versatility allows manufacturers to customize their cable management systems according to specific job requirements, ensuring the best fit for their CNC machinery.

Selecting the Right Cable Chain

When choosing a cable chain for a CNC application, several factors need to be considered

1. Cable Type and Size The type of cables and hoses being used will determine the size and configuration of the cable chain. It is crucial to ensure that the chain accommodates the cables without excessive bending or pinching.

2. Working Environment The environment in which the CNC machine operates plays a significant role in cable chain selection. Factors such as temperature, humidity, and exposure to chemicals can affect the material choice for the cable chain.

3. Travel Distance and Speed The distance the chain needs to cover and the speed at which it will operate influence the design. Higher speeds may require more robust chains to withstand the additional stress.

4. Installation Space The available space for installation is another critical consideration. Some CNC machines may have limited space, requiring more compact cable chain solutions.

Conclusion

In summary, cable chains are essential components in the effective operation of CNC machines. By providing protection, improving efficiency, and enhancing flexibility, they significantly contribute to the overall performance of CNC applications. Whether you are a manufacturer looking to optimize your machining processes or an engineer seeking to design more reliable systems, understanding the role of cable chains can lead to better choices and improved outcomes in CNC machining. As technology continues to evolve, the importance of these small yet effective components will only grow, making them an integral part of future advancements in the industry.