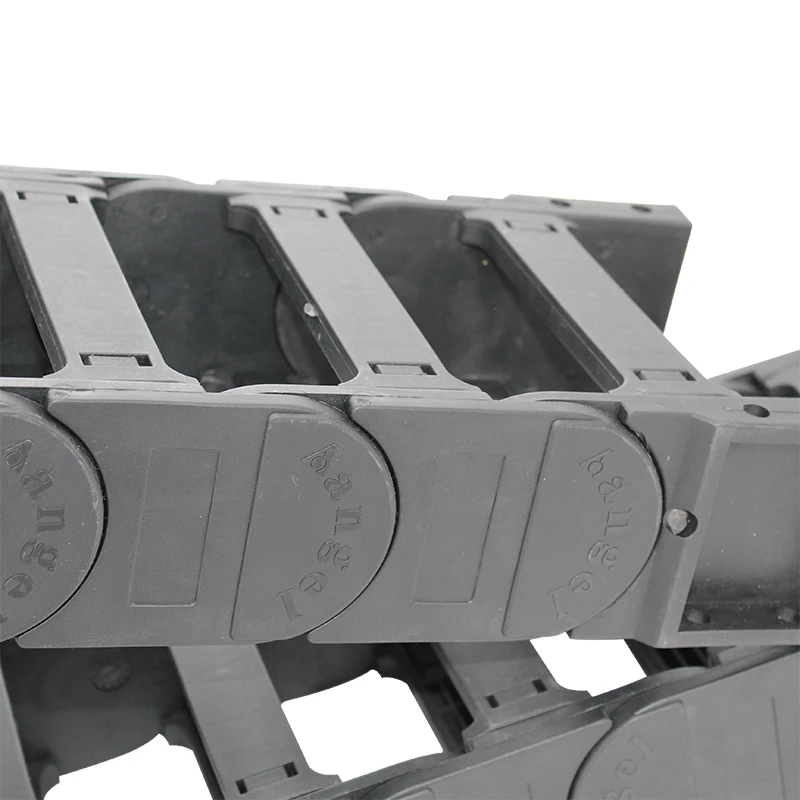

cable cat track

For companies and industries relying on machinery with moving parts, cable cat tracks are indispensable. These dynamic systems, also known as cable carriers or drag chains, ensure that cables and hoses remain protected and guided, preventing damage during the operation of machinery. Delving into the realm of cable cat tracks uncovers insights into their critical role in maintaining efficient and safe industrial operations.

Trustworthiness in the application of cable cat tracks arises from the quality and reputability of manufacturers. Companies specializing in these systems prioritize rigorous testing regimes to verify their products against stringent safety and performance metrics. This process includes lifecycle testing that simulates years of operational wear and tear, ensuring that the tracks can withstand real-world conditions. Certifications from industry-standard bodies further bolster confidence in these solutions, guaranteeing that customers receive products built to last. The benefits of cable cat tracks are not confined to preventing damage and ensuring safety but extend to optimizing system performance. By organizing and protecting cables, these tracks enable smoother operations and more efficient power delivery. Users often note improved cycle times in automated systems, attributable to the reduced mechanical resistance and enhanced organization that cable cat tracks provide. Looking ahead, the development of cable cat tracks is poised to embrace technological advancements such as IoT integration and smart monitoring. These innovations promise real-time diagnostics and maintenance alerts, allowing operators to address potential issues before they escalate into major problems. Smart cable tracks equipped with sensors will offer insights into performance metrics, temperature variations, and stress levels, ushering in a new era of predictive maintenance. In summary, cable cat tracks are vital components that uphold the integrity and performance of a myriad of industrial applications. Their careful design and implementation not only prolong the life of equipment but also enhance operational efficiency and safety. For sectors seeking reliable and robust cable management solutions, cable cat tracks present a crucial investment in ensuring seamless, uninterrupted production.

Trustworthiness in the application of cable cat tracks arises from the quality and reputability of manufacturers. Companies specializing in these systems prioritize rigorous testing regimes to verify their products against stringent safety and performance metrics. This process includes lifecycle testing that simulates years of operational wear and tear, ensuring that the tracks can withstand real-world conditions. Certifications from industry-standard bodies further bolster confidence in these solutions, guaranteeing that customers receive products built to last. The benefits of cable cat tracks are not confined to preventing damage and ensuring safety but extend to optimizing system performance. By organizing and protecting cables, these tracks enable smoother operations and more efficient power delivery. Users often note improved cycle times in automated systems, attributable to the reduced mechanical resistance and enhanced organization that cable cat tracks provide. Looking ahead, the development of cable cat tracks is poised to embrace technological advancements such as IoT integration and smart monitoring. These innovations promise real-time diagnostics and maintenance alerts, allowing operators to address potential issues before they escalate into major problems. Smart cable tracks equipped with sensors will offer insights into performance metrics, temperature variations, and stress levels, ushering in a new era of predictive maintenance. In summary, cable cat tracks are vital components that uphold the integrity and performance of a myriad of industrial applications. Their careful design and implementation not only prolong the life of equipment but also enhance operational efficiency and safety. For sectors seeking reliable and robust cable management solutions, cable cat tracks present a crucial investment in ensuring seamless, uninterrupted production.