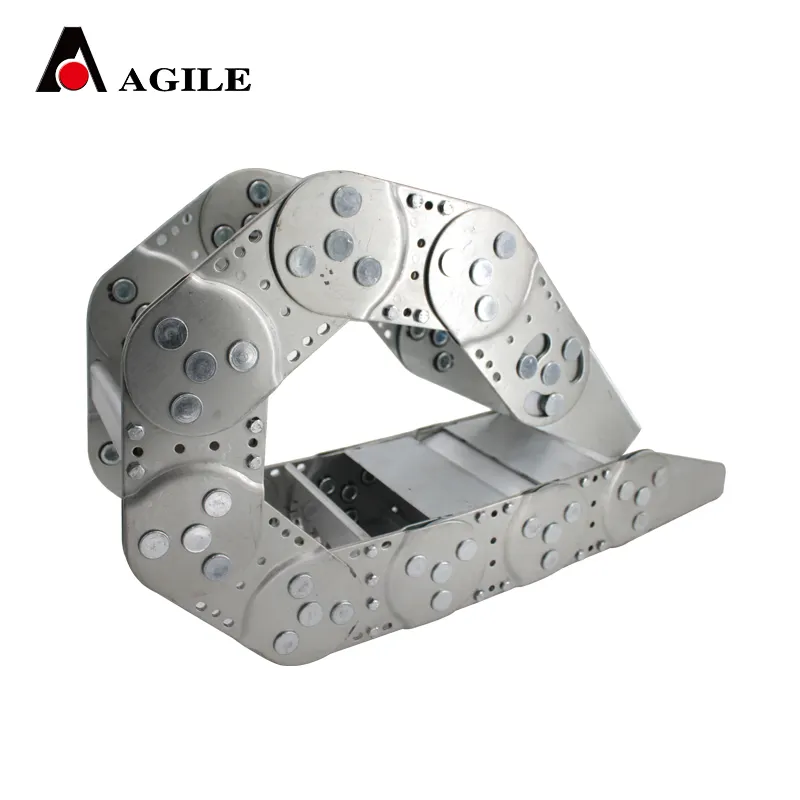

cable cat track

Cable cat tracks, often recognized as cable carriers, hold a prominent place in the world of engineering and industrial automation. Their primary function is to guide and protect cables and hoses connected to moving machinery, ensuring an efficient and safe transfer of electrical power, data, and fluids. Choosing the right cable cat track can profoundly influence the performance and reliability of your machinery. Here, we delve into why these components are indispensable and how to leverage their benefits effectively.

Evaluating the suitability of a cable cat track extends beyond its mechanical specifications. Important considerations encompass environmental factors such as temperature extremes, exposure to abrasive particles, and regulatory compliance specific to industries such as healthcare and food services. Thus, a strategic selection process often involves a holistic assessment, weighing the operational conditions and anticipated lifecycle of the machinery. Innovative advancements in cable cat track technology, notably the integration of smart monitoring features, have also revolutionized industry standards. Equipped with sensors and real-time monitoring capabilities, contemporary cable carriers can predict potential errors, prompting preemptive maintenance and reducing unforeseen breakdowns. This investment in intelligent systems augments overall accountability and trust in an enterprise's capabilities by preventing failure and ensuring a reliable production continuum. The flexibility of cable cat tracks extends into the realm of customization, an essential factor for businesses seeking tailored solutions. Custom designs can accommodate special requirements such as heightened load capacities, specific geometric constraints, or increased thermal resistance. Manufacturers proficiently coordinate with industries to develop bespoke configurations that seamlessly integrate with unique operational demands, further enhancing credibility and trustworthiness. In conclusion, the relevance and indispensability of cable cat tracks in modern industry underscore their importance as a linchpin in ensuring operational excellence. Through careful selection and strategic implementation, organizations can harness their full potential reducing downtime, minimizing costs, maximizing machinery lifespan, and enhancing overall productivity. As industry needs evolve, the continual adaptation and innovation within cable cat track technology ensure these vital components will remain at the forefront of industrial advancement, maintaining their role as guardians of operational efficiency and reliability.

Evaluating the suitability of a cable cat track extends beyond its mechanical specifications. Important considerations encompass environmental factors such as temperature extremes, exposure to abrasive particles, and regulatory compliance specific to industries such as healthcare and food services. Thus, a strategic selection process often involves a holistic assessment, weighing the operational conditions and anticipated lifecycle of the machinery. Innovative advancements in cable cat track technology, notably the integration of smart monitoring features, have also revolutionized industry standards. Equipped with sensors and real-time monitoring capabilities, contemporary cable carriers can predict potential errors, prompting preemptive maintenance and reducing unforeseen breakdowns. This investment in intelligent systems augments overall accountability and trust in an enterprise's capabilities by preventing failure and ensuring a reliable production continuum. The flexibility of cable cat tracks extends into the realm of customization, an essential factor for businesses seeking tailored solutions. Custom designs can accommodate special requirements such as heightened load capacities, specific geometric constraints, or increased thermal resistance. Manufacturers proficiently coordinate with industries to develop bespoke configurations that seamlessly integrate with unique operational demands, further enhancing credibility and trustworthiness. In conclusion, the relevance and indispensability of cable cat tracks in modern industry underscore their importance as a linchpin in ensuring operational excellence. Through careful selection and strategic implementation, organizations can harness their full potential reducing downtime, minimizing costs, maximizing machinery lifespan, and enhancing overall productivity. As industry needs evolve, the continual adaptation and innovation within cable cat track technology ensure these vital components will remain at the forefront of industrial advancement, maintaining their role as guardians of operational efficiency and reliability.