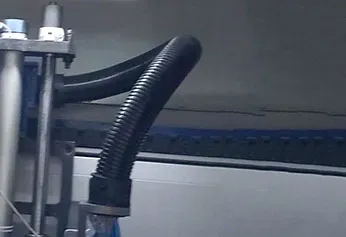

cable carrier track

Understanding Cable Carrier Tracks Essential Components for Efficient Cable Management

In today's dynamic industrial landscape, efficient cable management is crucial for maintaining operational integrity and safety. Among the various solutions available, cable carrier tracks, commonly known as cable chains or cable carriers, play a pivotal role. These systems not only facilitate the organized movement of cables but also enhance the longevity of both cables and equipment. This article delves into the significance, functionality, and advantages of cable carrier tracks.

What is a Cable Carrier Track?

A cable carrier track is a specialized mechanical assembly designed to securely hold and guide cables, hoses, and wires in motion. These tracks are typically made from durable materials such as plastic or metal and come in various designs to suit specific applications. They are commonly employed in settings where machines or components experience linear or rotary movement, such as CNC machines, robotics, and automotive production lines.

The Functionality of Cable Carrier Tracks

The primary function of a cable carrier track is to provide a structured pathway for cables and hoses, protecting them from wear and tear as they move with machinery. The design of these tracks incorporates a series of interconnected links that create a flexible yet sturdy channel for the cables. This allows complex routing while preventing tangling or excessive bending that could lead to damage.

The movement of cables through these tracks is facilitated by their smooth internal finish and the use of rollers or gliders, which reduce friction. When implemented correctly, cable carriers can accommodate multiple cables, thereby optimizing space and improving the overall aesthetics of a work environment.

Advantages of Using Cable Carrier Tracks

1. Enhanced Durability and Protection

One of the most significant advantages of cable carrier tracks is the protection they offer for sensitive cabling systems. By providing a dedicated and secure pathway, they mitigate the risks of physical damage from movement, abrasion, or environmental factors. This can significantly increase the lifespan of cables, resulting in fewer replacements and lower maintenance costs over time.

2. Improved Safety

cable carrier track

Cable mismanagement can lead to hazards such as tripping, electrical shorts, and fire risks. By employing cable carrier tracks, companies can minimize these risks. Cables are neatly organized and secured, promoting a safer working environment. Furthermore, many cable carriers are designed with features that enhance safety, such as locking mechanisms that ensure cables stay in place during operations.

3. Flexibility and Customization

Cable carrier tracks are available in numerous configurations and sizes, allowing for customization based on specific industrial requirements. Manufacturers often offer modular systems that can be easily adjusted or expanded as needs evolve. This flexibility makes them suitable for a wide range of applications, from small-scale operations to large industrial setups.

4. Efficient Space Utilization

In many industrial settings, space is at a premium. Traditional cable management systems, such as bulk cabling or untethered wires, can create clutter and reduce efficiency. Cable carrier tracks facilitate better organization and space utilization, allowing businesses to maximize their available area while minimizing the risk of cable damage.

Applications of Cable Carrier Tracks

The versatility of cable carrier tracks makes them ideal for various applications across multiple industries. Some common uses include

- Robotics Ensuring secure and unobstructed movement of power and signal cables in robotic arms and automated systems. - CNC Machines Protecting and guiding cables in high-motion environments, reducing wear from machinery operation. - Automotive Manufacturing Streamlining the cable management process in assembly lines, enhancing safety and efficiency. - Elevators and Conveyor Systems Providing a safe pathway for cables that control movement and operations.

Conclusion

In conclusion, cable carrier tracks are indispensable in modern industrial environments. Their ability to enhance cable management, improve safety, and increase operational efficiency makes them a fundamental part of many systems. As technology continues to evolve, the importance of smart, organized cable solutions like carrier tracks will only grow, solidifying their role as essential components in the toolkit of engineers and facility managers alike. Investing in quality cable carrier tracks not only promises immediate benefits but also supports long-term operational success.