cable carrier track

The Essential Role of Cable Carrier Tracks in Modern Industries

In the ever-evolving landscape of modern industries, the need for efficient and organized cable management has become paramount. One of the most innovative solutions to emerge in this realm is the cable carrier track, a system designed to facilitate the safe and efficient movement of cables and hoses in various applications. In this article, we will delve into the significance, functionality, applications, and benefits of cable carrier tracks in contemporary industrial settings.

Understanding Cable Carrier Tracks

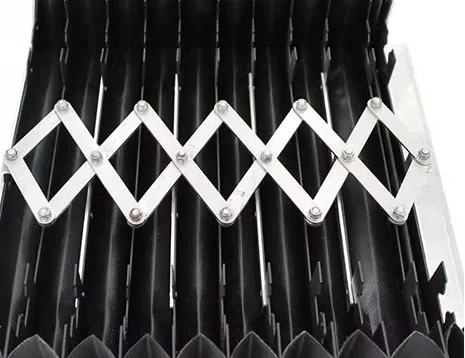

Cable carrier tracks, also known as cable drag chains or energy chains, are engineered systems that support and protect cables and hoses as they move. These tracks consist of interconnected links that allow for flexible movement while maintaining a structured pathway. They are usually made from durable materials such as plastic or metal, which can withstand harsh environments and protect against abrasion, heat, and chemicals.

The primary function of a cable carrier track is to keep cables organized and prevent tangling or wear that can occur in dynamic applications. They are particularly beneficial in environments where cables need to move alongside machinery or equipment, such as in manufacturing plants, robotics, and CNC machining centers.

The Importance of Cable Management

Effective cable management is crucial for safety, efficiency, and maintenance in any industrial setup. Disorganized cables can lead to accidents, equipment malfunctions, and increased downtime. By using cable carrier tracks, businesses can significantly reduce these risks. These systems ensure that cables are secured, allowing them to move freely without the danger of entanglement or damage.

Moreover, cable carrier tracks simplify maintenance procedures. When cables are neatly organized and easily accessible within their tracks, technicians can quickly identify and resolve issues, minimizing downtime and maintaining productivity.

Applications of Cable Carrier Tracks

Cable carrier tracks find applications across a wide variety of industries and settings

. Some prominent areas include1. Manufacturing and Automation In assembly lines and automated processes, cable carrier tracks allow for smooth movement of cables powering tools, sensors, and other machinery. They ensure that cables are not pinched or stressed during operation.

cable carrier track

2. Robotics Robotic systems often require a dynamic yet organized cabling solution. Cable carrier tracks help maintain the integrity of wires and hoses, allowing robots to move with precision without risking damage to their essential connections.

3. CNC Machining The intricate movements of CNC machines necessitate secure cable management. Cable carrier tracks keep wires organized, reducing wear and enhancing the efficiency of machining operations.

4. Aerospace and Automotive In the aerospace and automotive industries, cable carrier tracks manage complex cable routing in tight spaces, ensuring that systems remain functional and reliable even under strenuous conditions.

The Benefits of Implementing Cable Carrier Tracks

The advantages of integrating cable carrier tracks into industrial settings are numerous

- Enhanced Safety By organizing cables and hoses, the risk of tripping hazards and equipment malfunctions is minimized, contributing to a safer work environment.

- Increased Durability Quality cable carrier tracks are designed to withstand various environmental conditions, protecting cables from wear and tear that can lead to costly repairs and replacements.

- Improved Efficiency With clutter-free workspaces and streamlined cable management, companies can enhance productivity. Streamlined processes often lead to faster production rates and reduced operational costs.

- Customizability Cable carrier tracks can be tailored to fit specific applications. With various sizes, materials, and configurations available, businesses can implement solutions that meet their unique needs.

Conclusion

In conclusion, cable carrier tracks play a pivotal role in modern industries where cable management is essential for safety, efficiency, and productivity. Their ability to protect cables, streamline operations, and enhance maintenance procedures makes them invaluable assets in any industrial setting. As technology continues to advance and industries become more automated, the significance of effective cable management solutions, like cable carrier tracks, will only continue to grow, shaping the future of industrial operations.