cable carrier systems

Understanding Cable Carrier Systems An Essential Component of Modern Industry

In the fast-paced world of modern industry, efficiency and safety are paramount. One crucial aspect of maintaining these standards is the effective management and routing of cables, which is where cable carrier systems come into play. These sophisticated systems are designed to support and protect cables in various applications, providing a reliable solution for industries ranging from manufacturing to automation.

What Are Cable Carrier Systems?

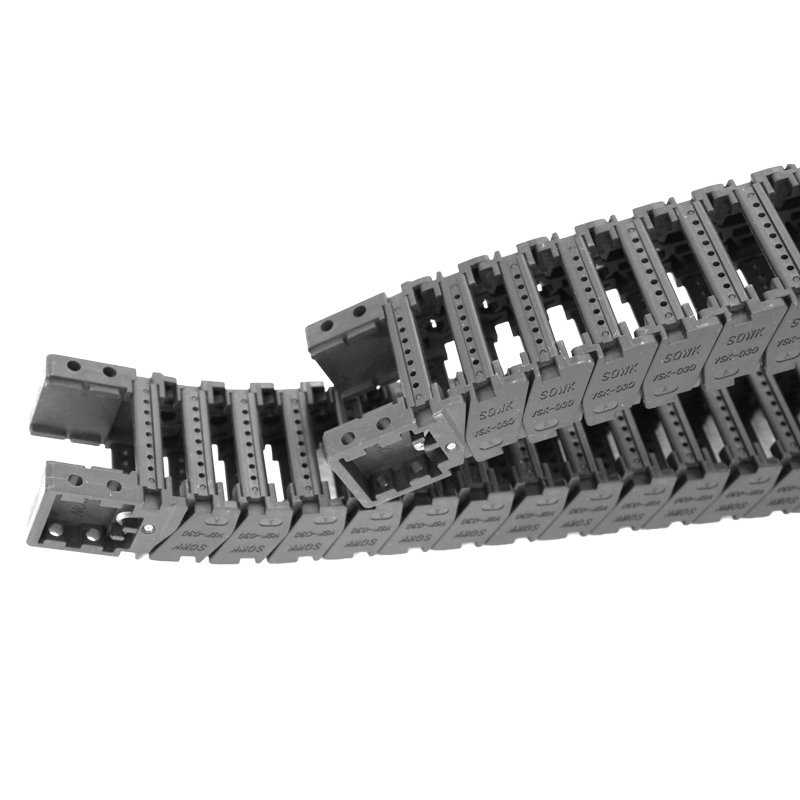

Cable carrier systems, also known as drag chains or cable track systems, are engineering solutions that guide and contain cables, hoses, and other flexible materials. These systems are essential in environments where movement is constant—such as machinery, robotics, and conveyor systems—allowing cables to move freely without getting tangled or damaged. By providing structured pathways, cable carriers can significantly enhance the longevity of cables and reduce downtime caused by maintenance issues.

Components of Cable Carrier Systems

A typical cable carrier system consists of several components, including the carrier chain, cable support brackets, and connection points. The carrier chain is the backbone of the system, made from durable materials like plastic, aluminum, or steel to withstand rigorous use. The design usually incorporates a series of interconnected links that create a flexible channel for cables. The size and configuration of these chains can vary depending on the specific requirements of the application.

Cable support brackets play a vital role in securing the carrier to moveable parts of machinery, ensuring that it stays in place during operation. These brackets can be adjustable, allowing for the customization of the system based on varying lengths and types of cables. Connection points facilitate the integration of the cable carrier system into existing infrastructure, making it easy to retrofit or update machinery without complete overhauls.

Benefits of Using Cable Carrier Systems

1. Protection and Durability By providing a protective enclosure for cables, these systems minimize wear and tear, shielding cables from mechanical damage, chemicals, and environmental hazards. This protection extends the lifespan of cables and reduces the risk of failures that could lead to costly downtime.

cable carrier systems

2. Enhanced Mobility Cable carriers allow for smooth movement even in dynamic environments. Whether the application involves vertical, horizontal, or complex motion, cable carriers can accommodate various paths, ensuring that cables are guided seamlessly without the risk of kinking or snagging.

3. Improved Organization In industrial settings, the management of cables can quickly become chaotic, especially with multiple cables running to various devices and sensors. Cable carrier systems help organize cables efficiently, reducing clutter and simplifying maintenance. This organization aids in troubleshooting and reduces the likelihood of erroneous connections.

4. Safety Considerations The use of cable carriers also enhances workplace safety by reducing the risk of trips and falls caused by exposed cables. Safety is a critical consideration in any industrial operation, and properly managed cables contribute to a safer working environment for employees.

5. Flexibility and Customization Cable carrier systems are highly customizable. Manufacturers can design carriers specific to the unique requirements of their operations, including varying bend radii, lengths, and materials to suit different environments and applications.

Applications of Cable Carrier Systems

The versatility of cable carrier systems means they are used in a wide range of industries, including

- Manufacturing In automated assembly lines, cable carriers manage power and signal cables for machinery. - Robotics For robotic systems that require extensive movement, cable carriers provide a reliable solution for guiding wires and hoses. - Construction Cranes and other heavy equipment utilize cable carriers to manage control cables effectively. - Automotive In automotive manufacturing plants, cable carriers streamline the movements of machines and tooling equipment, ensuring that production lines run smoothly.

Conclusion

In summary, cable carrier systems are an invaluable component of modern industrial operations. Offering protection, organization, and safety, these systems ensure that cables and hoses function efficiently in dynamic environments. As technology continues to evolve, the role of cable carriers will remain crucial in streamlining processes and enhancing operational efficiency. By investing in quality cable carrier systems, industries can achieve greater reliability, safety, and productivity in their operations, paving the way for continued innovation and success in the years to come.