Cable Systems for Lifting Applications in Industrial Hoisting Solutions

The Importance of Cable Carriers for Hoists

In modern industrial applications, hoisting systems play a pivotal role in lifting and moving heavy loads safely and efficiently. At the core of these systems is a crucial component the cable carrier, also known as a drag chain or energy chain. This article explores the function, benefits, and considerations of using cable carriers in hoisting applications.

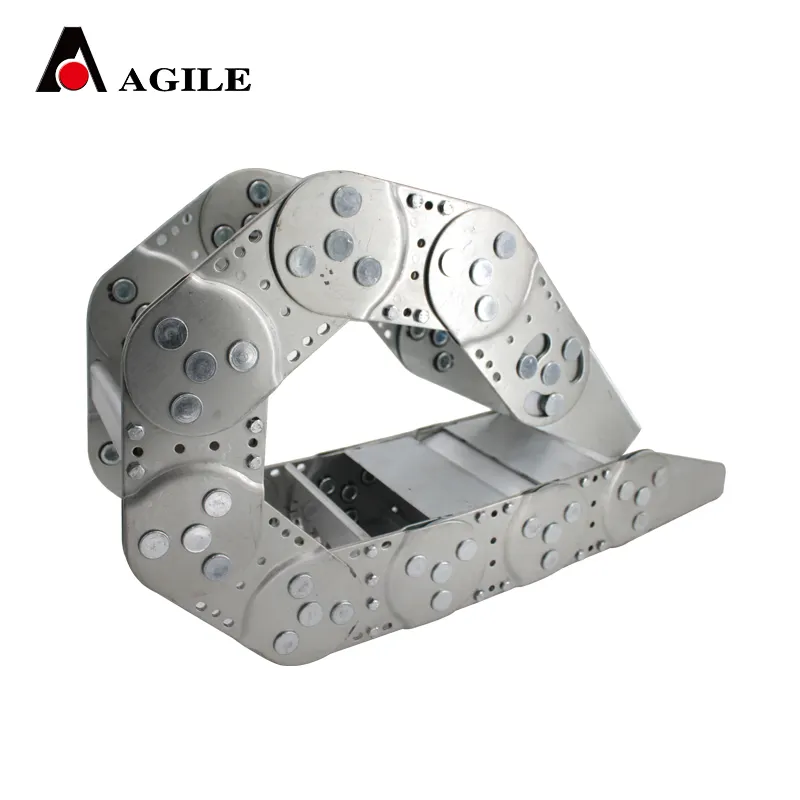

Understanding Cable Carriers

Cable carriers are mechanical devices designed to guide and protect flexible cables, hoses, and other types of elongated components during movement. They serve as a supportive bridge that encases the cables while allowing them to move freely as the hoist operates. Typically constructed from durable materials such as plastic or metal, cable carriers come in various shapes and sizes to accommodate different application requirements.

Functionality in Hoisting Systems

When hoists are employed to lift heavy loads, the movement can put significant stress on the cables and hoses involved. Without proper guidance, these cables can become tangled, kinked, or damaged, which can lead to operational failures or even hazardous situations. Cable carriers mitigate these risks by providing a controlled pathway for the cables. They not only protect the cables from physical damage but also ensure a smooth and predictable range of motion. This reduces wear and tear on the cables and prolongs their lifespan, leading to lower maintenance costs and increased operational efficiency.

Benefits of Using Cable Carriers

2. Enhanced Mobility By using a cable carrier, the movement of cables is smooth and unrestricted, allowing for better maneuverability of the hoist. This is particularly important in applications with high-speed or repetitive lifting tasks.

cable carrier for hoist

3. Reduced Downtime With improved protection and mobility, the likelihood of cable failure decreases significantly. This results in less unplanned downtime, which is crucial for maintaining productivity in industrial settings.

4. Customized Solutions Cable carriers can be tailored to specific requirements, taking into account the size, weight, and type of cables used, as well as the operational environment. This versatility makes them suitable for a wide range of hoisting systems.

5. Safety Improvements By keeping cables organized and protected, cable carriers reduce the risk of accidents caused by entanglement or snagging. This enhances safety for operators and other personnel in the vicinity of the hoisting operation.

Considerations for Selecting Cable Carriers

When choosing a cable carrier for a hoisting system, several factors must be taken into consideration. First, the carrier must be compatible with the types and dimensions of the cables being used. Additionally, it's essential to assess the environment in which the hoist will operate. Factors such as temperature extremes, exposure to chemicals, and the presence of contaminants can influence the selection of materials for the cable carrier.

Furthermore, the expected range of motion and the speed of operation will determine the design of the carrier. Some applications may require carriers with higher flexibility and bending radii, while others may prioritize robustness and load-bearing capacity.

Conclusion

In conclusion, cable carriers are an integral component of hoisting systems, serving to protect and guide cables efficiently. Their role in enhancing mobility, reducing downtime, and improving safety cannot be overstated. By carefully selecting the appropriate cable carrier for a specific application, businesses can ensure that their hoisting operations run smoothly and effectively, ultimately leading to increased productivity and safety in the workplace. As industries continue to evolve, the importance of reliable, effective cable management solutions like cable carriers will remain a priority for optimizing hoisting systems.