Cable Systems for Lifting Applications in Hoist Mechanisms and Equipment

The Importance of Cable Carriers in Hoisting Applications

In modern industrial settings, hoisting systems play a crucial role in lifting, lowering, and moving heavy loads with precision and safety. A key component that enhances the efficiency and reliance of these systems is the cable carrier, also known as a drag chain or cable chain. This article explores the significance of cable carriers in hoisting applications, their benefits, and considerations for selecting the right type.

Understanding Cable Carriers

Cable carriers are protective and guiding systems designed to manage and organize cables, hoses, and other flexible materials in dynamic applications. These carriers support the safe movement of electrical cables and fluid lines, allowing them to move with a hoisting mechanism without becoming tangled or damaged. They are commonly used in cranes, lifts, and other lifting equipment, providing both functionality and safety.

Benefits of Cable Carriers in Hoisting Systems

1. Enhanced Protection One of the primary benefits of cable carriers is their ability to protect cables from mechanical damage. In hoisting applications where cables are frequently subjected to bending and movement, having a dedicated carrier minimizes the risk of wear and tear, extending the lifespan of the cables. This protection is crucial as damaged cables can lead to equipment failure, safety hazards, and costly downtime.

2. Organized Cable Management In a busy industrial environment, multiple cables can easily become intertwined, leading to confusion and potential accidents. Cable carriers offer organized pathways for the cables, ensuring that they are neatly arranged and easily accessible. This organized setup not only facilitates maintenance but also improves overall operational efficiency.

3. Flexibility and Range of Motion Cable carriers are engineered to provide freedom of movement along defined paths. They can accommodate various hoisting motions, whether vertical, horizontal, or diagonal, ensuring that cables stay aligned with the hoisting equipment. This flexibility is vital in applications where loads may shift or swing, allowing for smooth operation without hindrance.

4. Customization Different hoisting systems have unique requirements based on the load capacity, workspace dimensions, and operational environment. Cable carriers come in various sizes, shapes, and materials, allowing for customization to fit specific applications. This adaptability ensures optimal performance, whether in a factory, construction site, or warehouse.

5. Reduced Downtime With the protection and organization that cable carriers provide, maintenance becomes more straightforward. Operators can quickly identify issues, perform necessary repairs, and replace components without extensive disassembly. This capability significantly reduces downtime, allowing for continued production and efficiency.

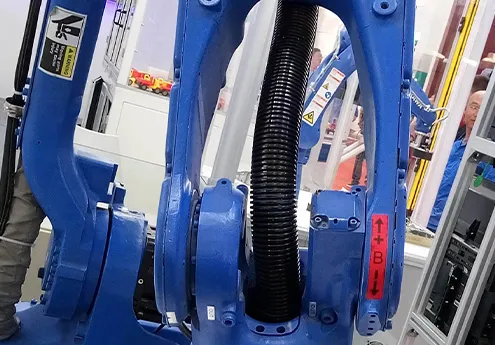

cable carrier for hoist

Key Considerations for Selection

When choosing a cable carrier for hoisting applications, several factors should be considered

- Load Capacity Assess the weight of the cables and any additional equipment that the carrier will need to support. A carrier must have a sufficient load capacity to avoid failure during operation.

- Travel Distance The length and range of motion required for the hoisting application will dictate the type and size of the cable carrier needed. Longer travel distances may require more robust or specialized designs.

- Environmental Factors Different working environments can present unique challenges, such as exposure to chemicals, extreme temperatures, or moisture. Selecting a cable carrier made from appropriate materials designed to withstand these conditions is essential for longevity.

- Bend Radius The radius at which cables can bend without damage is a critical consideration. Ensure that the selected cable carrier can accommodate the necessary bend radius for the specific cables being used.

- Compatibility Finally, ensure that the cable carrier is compatible with the existing hoisting equipment and other components. This compatibility is crucial for seamless integration and function.

Conclusion

In conclusion, cable carriers are essential components in hoisting applications, offering enhanced protection, organized cable management, flexibility, and reduced downtime. By understanding the importance of these carriers and considering the key factors during selection, businesses can significantly improve the reliability and safety of their hoisting systems. Investing in high-quality cable carriers not only prolongs the lifespan of cables and equipment but also creates a safer and more efficient work environment, essential for any modern industrial operation.