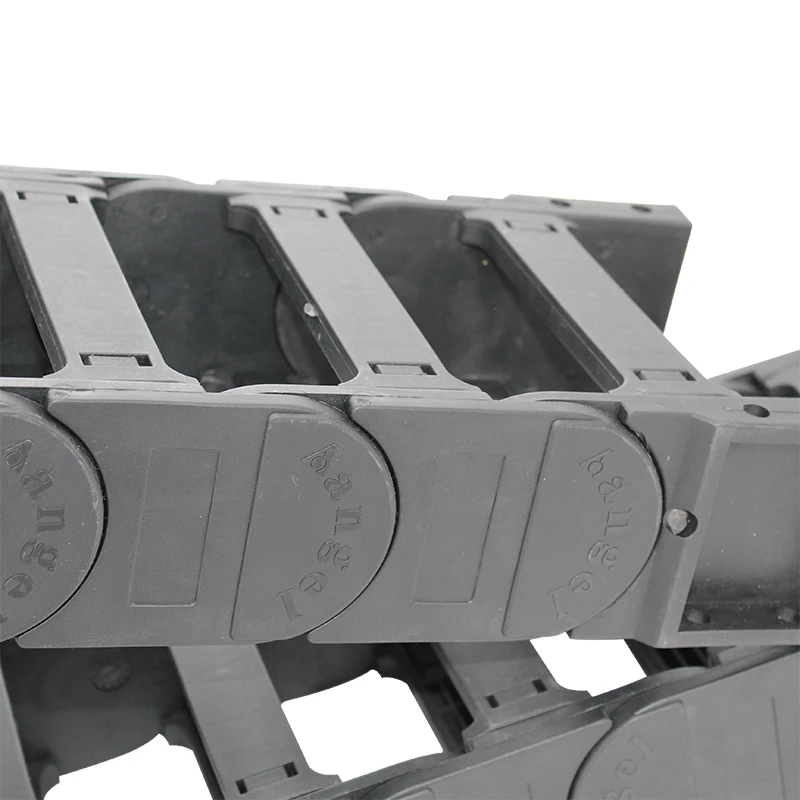

flexible cable carrier

Navigating the intricate landscape of modern automation and machinery requires tools that balance reliability, efficiency, and durability. Among these indispensable tools, cable carriers stand out as a crucial component that often goes unnoticed until it proves its worth in maintaining seamless operations. Initially, cable carriers might seem like simple conduits, but their impact on machinery functionality is profound, championing not just the organization of cables but also protecting them from wear and external elements.

Trustworthiness in the use of cable carriers comes from documented case histories and certifications. Industrial sectors, including automotive, aerospace, and manufacturing, frequently rely on certified cable carriers meeting ISO standards for quality and performance. Companies often publish transparent, data-backed assessments of their products, which can be pivotal in building trust. Furthermore, testimonials from automation specialists and engineers often highlight successful implementations, reinforcing the safety and reliability that these components bring to complex systems. As automation and machinery continue to advance, keeping cables precisely managed remains critical. For professionals responsible for the upkeep of these systems, investing in high-quality cable carriers is a decision that aligns with both operational excellence and cost-efficiency. Those in the field who share their positive experiences with these components often note the peace of mind they bring, backed by a solid foundation of technical expertise and industry trust. In sum, cable carriers are not mere accessories; they are essential to the backbone of efficient and reliable machinery operations. Selecting and implementing the appropriate cable carrier involves a comprehensive understanding of the machinery’s requirements and the operational environment. As the industrial landscape evolves, staying informed about the latest advancements in cable carrier technology helps ensure that your systems are not only operationally sound but also optimally efficient, safe, and ready for future challenges.

Trustworthiness in the use of cable carriers comes from documented case histories and certifications. Industrial sectors, including automotive, aerospace, and manufacturing, frequently rely on certified cable carriers meeting ISO standards for quality and performance. Companies often publish transparent, data-backed assessments of their products, which can be pivotal in building trust. Furthermore, testimonials from automation specialists and engineers often highlight successful implementations, reinforcing the safety and reliability that these components bring to complex systems. As automation and machinery continue to advance, keeping cables precisely managed remains critical. For professionals responsible for the upkeep of these systems, investing in high-quality cable carriers is a decision that aligns with both operational excellence and cost-efficiency. Those in the field who share their positive experiences with these components often note the peace of mind they bring, backed by a solid foundation of technical expertise and industry trust. In sum, cable carriers are not mere accessories; they are essential to the backbone of efficient and reliable machinery operations. Selecting and implementing the appropriate cable carrier involves a comprehensive understanding of the machinery’s requirements and the operational environment. As the industrial landscape evolves, staying informed about the latest advancements in cable carrier technology helps ensure that your systems are not only operationally sound but also optimally efficient, safe, and ready for future challenges.