Flexible Cable and Hose Management Solutions for Efficient Motion Systems

Understanding Cable and Hose Carrier Systems

In modern industrial environments, the seamless operation of machinery and equipment is paramount for efficiency and productivity. One integral component that facilitates this is the cable and hose carrier system. These systems play a crucial role in protecting and managing the movement of cables, hoses, and other flexible connections in various applications. Whether in manufacturing, robotics, or heavy machinery, understanding the importance and functionality of these carriers is essential for optimizing operations.

What Are Cable and Hose Carrier Systems?

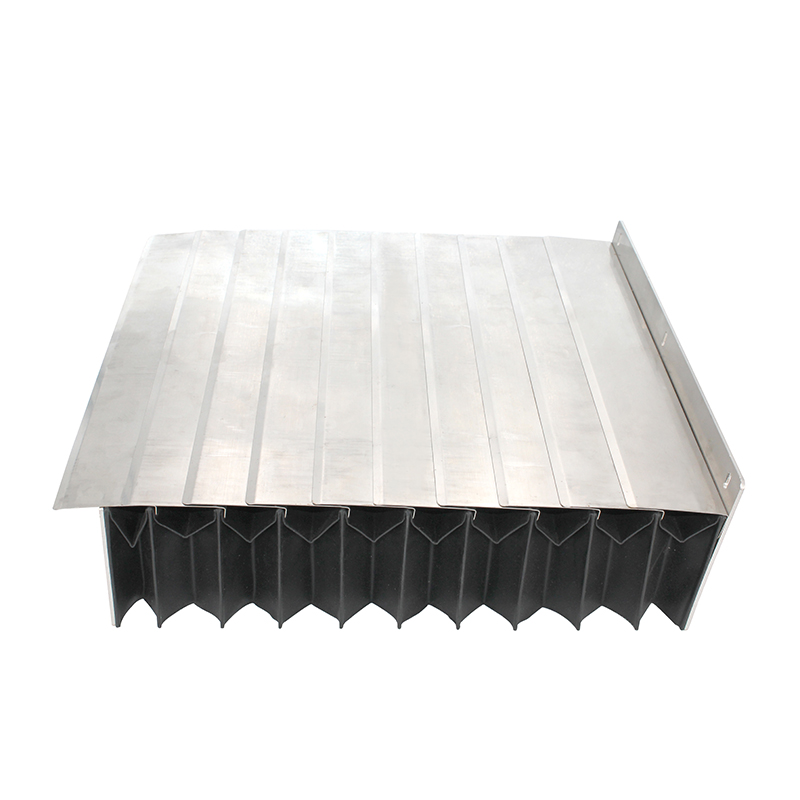

Cable and hose carrier systems, often referred to as energy chains or drag chains, are designed to guide and protect electrical cables, hydraulic hoses, pneumatic tubes, and other flexible media, while allowing them to move freely and flexibly. These systems come in various shapes, sizes, and materials, tailored to meet specific industry needs. By providing a designated pathway for these components, they prevent wear and tear, minimize entanglement, and reduce the risk of damage during motion.

Benefits of Using Cable and Hose Carriers

1. Protection from Damage One of the primary functions of cable and hose carrier systems is to safeguard cables and hoses from external hazards such as dirt, debris, and mechanical stress. This protection prolongs the lifespan of cables and hoses, reducing replacement costs and downtime.

2. Improved Mobility These systems are designed to accommodate the dynamic movement of machinery. They allow for smooth and uninterrupted motion, enabling equipment to operate efficiently without the risk of tangling or snagging, which can lead to operational delays.

3. Flexibility in Design Cable and hose carrier systems can be customized to fit various applications and environments. Whether operating in confined spaces or harsh conditions, these carriers can be adapted to suit specific needs, thereby enhancing versatility in design and function.

cable and hose carrier systems

4. Simplified Maintenance By organizing cables and hoses within a defined pathway, maintenance becomes more straightforward. Technicians can easily access the cables for inspections or replacements, increasing service efficiency and reducing downtime.

5. Weight Distribution When multiple cables and hoses are housed together, these carrier systems help distribute weight evenly, minimizing stress on individual components and ensuring balanced movement for machinery.

Application Areas

Cable and hose carrier systems find applications across a wide range of industries. In robotics, they facilitate movement by guiding power and control cables, ensuring that robotic arms can reach their full range of motion without hindrance. In manufacturing facilities, they are vital in conveyor systems, CNC machines, and heavy equipment, where multifaceted movements demand reliable cable management. Additionally, the automotive and aerospace industries also utilize these systems to maintain efficiency and safety in operations.

Choosing the Right System

Selecting the appropriate cable and hose carrier system involves considering several factors, including the type of cables or hoses being used, the environment in which they will operate, and the required range of motion. It is essential to work with reputable suppliers who can provide tailored solutions that meet specific operational needs.

Conclusion

In conclusion, cable and hose carrier systems are an essential component of modern machinery and equipment, offering protection, efficiency, and organization for flexible connections. By understanding their benefits and applications, businesses can leverage these systems to enhance productivity, reduce maintenance costs, and ensure smooth operations within their facilities. Proper implementation of cable and hose carriers not only safeguards investments in equipment but also contributes to a safer and more effective working environment.