Flexible Solutions for Cable and Hose Management Systems

Understanding Cable and Hose Carriers Enhancing Efficiency in Industrial Applications

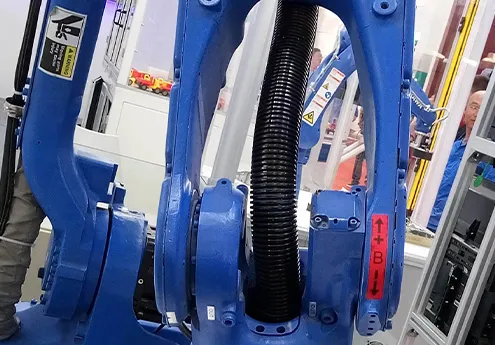

In the ever-evolving world of industrial automation and machinery, the need for efficient and organized cable management systems has never been more critical. One of the essential components fulfilling this need is the cable and hose carrier, often referred to as energy chain or drag chain. These carriers play a pivotal role in various applications, protecting cables and hoses while ensuring smooth movement and functionality of equipment.

What is a Cable and Hose Carrier?

A cable and hose carrier is a versatile system designed to manage and guide cables, hoses, or other flexible lines during the operation of machinery. It resembles a chain or track and is often made from durable materials like plastic, steel, or composite materials. This design allows for a seamless transition of cables and hoses as machinery moves, pivot, or operate across different axes.

Common Applications

Cable and hose carriers find their applications across a wide range of industries. Some common uses include

1. Manufacturing and Robotics In assembly lines and robotic applications, these carriers protect communication lines, power cables, and hoses, ensuring uninterrupted functionality. 2. CNC Machines CNC (Computer Numerical Control) machines involve complex movements. Cable carriers ensure that the cables feeding power and data to the machine remain untangled and are not exposed to wear and tear.

3. Conveyor Systems In conveyor systems, cable carriers enhance reliability by keeping the necessary cables organized as the conveyor moves and adjusts.

4. Material Handling Equipment Forklifts, cranes, and other material-handling equipment also rely on cable carriers, offering protection and organization during high-stress operations.

Benefits of Using Cable and Hose Carriers

cable and hose carrier

Implementing cable and hose carriers in industrial settings provides numerous advantages

1. Protection One of the primary functions of these carriers is to shield cables and hoses from wear, abrasion, and environmental hazards. This protection prolongs the life of sensitive components.

2. Improved Safety By keeping cables and hoses neatly organized, the risk of tripping or tangling can be significantly reduced, promoting a safer workplace.

3. Enhanced Mobility As machinery moves, tension on cables and hoses can lead to premature failure or disconnection. Cable carriers facilitate smooth movement, preventing undue stress on these components.

4. Ease of Maintenance With organized cables and hoses, maintenance becomes easier. Technicians can quickly identify issues and perform repairs without the challenges posed by entangled lines.

5. Customization Cable and hose carriers can be customized to fit specific needs. From choosing the right size and material to designing tailored guides and brackets, companies can optimize these systems for their unique applications.

Installation and Maintenance

When installing a cable and hose carrier, it is crucial to consider several factors. Choosing the correct size and style, accounting for the range of motion, and ensuring proper integration with existing systems are essential steps. Additionally, regular maintenance is key to ensuring long-term efficiency. This includes inspecting for wear and tear, ensuring that cables are securely fastened, and cleaning the carrier to prevent debris buildup.

Conclusion

As industrial operations become more complex and reliant on automation, the significance of cable and hose carriers will continue to grow. These systems not only foster organization and protect sensitive components but also enhance safety and operational efficiency. With a variety of applications across multiple industries, investing in high-quality cable and hose carriers is a strategic decision that can lead to improved productivity and reduced downtime. As technology advances, we can expect further innovations in the design and functionality of these essential components, making them an integral part of modern machinery and equipment.