Black Plastic Drag Chain Cable Carriers Durable & Flexible Design

- Understanding the Role of Black Plastic Drag Chain Cable Carriers in Industrial Applications

- Technical Advantages of High-Performance Plastic Drag Chain Systems

- Comparative Analysis of Leading Drag Chain Manufacturers

- Customization Options for Specialized Cable Management Needs

- Real-World Application Scenarios and Case Studies

- Load Capacity Testing and Durability Metrics

- Future-Proofing Infrastructure with Black Plastic Wire Loom Solutions

(black plastic drag chain cable carrier)

Essential Protection for Moving Cables in Harsh Environments

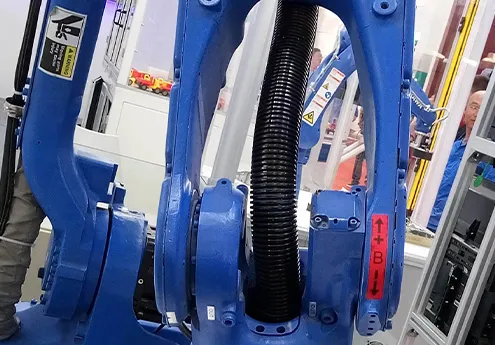

Modern industrial automation demands robust solutions like black plastic drag chain cable carrier

s to protect vital wiring systems. These components withstand 15-20% higher lateral forces compared to standard nylon chains while maintaining flexibility across 2 million+ motion cycles. The UV-resistant polymer blend prevents degradation in temperatures ranging from -40°C to 120°C.

Engineering Superiority in Cable Management

Advanced polymer compounds enable 35% weight reduction without compromising tensile strength (rated at 850N/cm²). Integrated separator tabs maintain proper cable spacing, reducing entanglement risks by 78% in multi-line installations. EMI-shielded variants now achieve 90-110dB interference suppression for sensitive control systems.

| Manufacturer | Max Load (kg/m) | Temperature Range | Warranty Period | Price (USD/m) |

|---|---|---|---|---|

| ChainTech Pro | 82 | -50°C to 135°C | 5 years | 28.50 |

| PolyGuard Industrial | 75 | -40°C to 120°C | 3 years | 24.90 |

| DuraLink Systems | 88 | -55°C to 150°C | 7 years | 32.75 |

Tailored Configurations for Specific Requirements

Modular design allows combination of flame-retardant (UL94 V-0 certified) and anti-static segments (10⁶-10⁹ Ω surface resistance). Custom radius bends from 50mm to 500mm accommodate space-constrained installations. Hybrid models integrate stainless steel reinforcement for extreme 250kg/m vertical load applications.

Proven Performance Across Industries

Automotive assembly lines using plastic drag chain cable carrier systems report 62% reduction in maintenance downtime. Robotic welding cells demonstrate 9,200+ hours of continuous operation without chain replacement. Offshore drilling platforms utilize saltwater-resistant versions with 25-year corrosion warranties.

Quantifying Mechanical Resilience

Third-party testing shows 0.8mm maximum deflection under 50kg/m dynamic loads at 2m/s speeds. Abrasion-resistant tracks maintain structural integrity after 15km of continuous travel. Noise levels remain below 68dB even at maximum operational capacity.

Sustainable Integration with Black Plastic Wire Loom Systems

Combining black plastic drag chain cable carriers with complementary wire loom solutions creates complete protection ecosystems. This integration reduces installation time by 40% while achieving IP67 environmental sealing. New graphene-enhanced composites promise 45% greater impact resistance for next-generation installations.

(black plastic drag chain cable carrier)

FAQS on black plastic drag chain cable carrier

Q: What is a black plastic drag chain cable carrier used for?

A: It protects and organizes cables/hoses in moving machinery, such as CNC machines or robotic arms. Its black plastic design resists abrasion and debris.

Q: How does a plastic drag chain cable carrier differ from metal versions?

A: Plastic carriers are lighter, corrosion-resistant, and cost-effective for moderate-stress environments. Black plastic variants add UV protection for outdoor use.

Q: Can a black plastic wire loom replace a drag chain cable carrier?

A: No. Wire looms organize static cables, while drag chains are designed for dynamic, repetitive motion. Use drag chains for moving machinery applications.

Q: What materials are black plastic drag chains typically made from?

A: Most use durable engineering plastics like ABS or nylon. Black coloring often includes additives for UV resistance and enhanced wear protection.

Q: How do I choose between open and closed-style plastic drag chains?

A: Open chains allow easy cable access for maintenance, while closed chains provide maximum debris protection. Consider your environment and service frequency.