Innovative Designs for Bellows and Protective Covers in Industrial Applications

The Importance of Bellows Way Covers in Industrial Applications

In the realm of industrial machinery, protecting the vulnerable components from external elements is crucial for ensuring longevity and reliable performance. One of the most effective solutions in this context is the use of bellows way covers. These protective devices are specifically designed to shield linear slides and other moving parts from dirt, debris, and coolant, which are common threats in industrial environments.

What Are Bellows Way Covers?

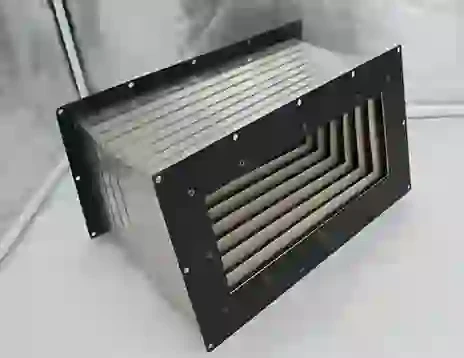

Bellows way covers, often referred to simply as bellows, are flexible coverings made from a variety of materials, including rubber, fabric, or vinyl. These materials are chosen for their durability and resistance to wear, allowing them to withstand the rigors of industrial use. Structurally, bellows consist of a series of pleats or folds, allowing them to expand and contract as moving parts operate. This design not only provides protection but also enables smooth movement, making them ideal for CNC machines, lathes, milling machines, and other equipment that relies on precise linear motion.

The Functionality and Benefits of Bellows Way Covers

The primary function of bellows way covers is to act as a barrier between sensitive machine parts and the environment. In workshops, flying particles, metal shavings, and coolant can rapidly accumulate and hinder the operational integrity of machinery. By deploying bellows, manufacturers can extend the lifespan of their equipment and reduce maintenance downtime.

In addition to their protective capabilities, bellows are designed to be lightweight yet sturdy, which helps maintain the overall efficiency of the machinery. Their flexibility allows them to conform to various shapes and sizes, making them suitable for a wide range of applications. Moreover, the installation of bellows way covers is typically straightforward, eliminating the need for complex modifications to existing equipment.

bellows way covers

Another significant advantage is the reduction of wear and tear on critical components. By keeping contaminants away from moving parts, bellows play a vital role in minimizing friction and extending the intervals between necessary maintenance. This leads to both cost savings and increased productivity, making bellows an indispensable part of many industrial settings.

Customization and Design Considerations

When selecting bellows way covers, customization is often necessary to ensure a proper fit for specific machinery. Manufacturers can provide bellows designed to accommodate unique dimensions and operational requirements. Factors like the amplitude of movement, the rate of extension, and the working environment are all critical in determining the appropriate design.

For instance, in environments where exposure to harsh chemicals is a concern, selecting materials that resist corrosive effects is vital. Likewise, if a machine operates in high-temperature settings, opting for heat-resistant bellows will enhance performance and safety.

Conclusion

In summary, bellows way covers are essential components in modern industrial applications, providing effective protection for machinery against environmental hazards. Their unique design, combined with versatile materials and the ability to customize for specific needs, makes them an ideal choice for safeguarding moving parts. As industries continue to evolve and innovate, the role of bellows way covers will only become more critical in ensuring the optimal performance and longevity of machinery. Investing in high-quality bellows not only promotes maintenance efficiency but also supports the overall productivity of manufacturing processes. For companies looking to improve their operational stability, incorporating bellows way covers into their equipment is a forward-thinking decision that is sure to yield long-term benefits.