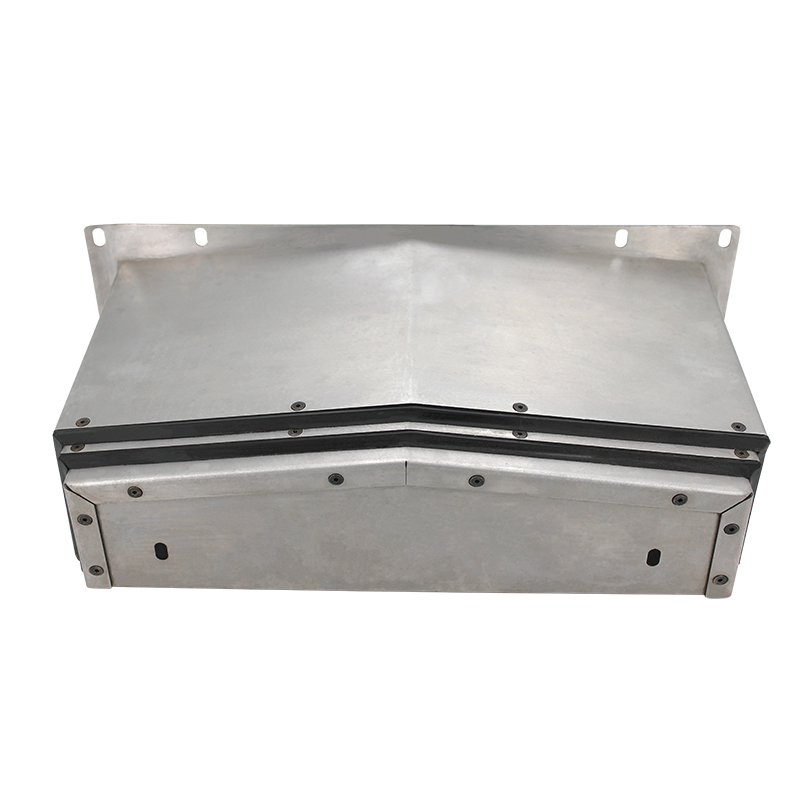

bellows for cnc machine

The Importance of Bellows for CNC Machines

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by allowing for precision and automation in machining processes. These machines perform tasks that require high accuracy and repeatability, making them invaluable in sectors like aerospace, automotive, and electronics. One of the often-overlooked components that play a critical role in the performance and longevity of CNC machines is the bellows.

The Importance of Bellows for CNC Machines

In a CNC environment, numerous materials are processed, often resulting in shavings, dust, and other particles that can accumulate on critical machine parts. Without proper protection, these contaminants can lead to significant damage over time. Bellows act as shields, preventing such debris from entering vulnerable areas and ensuring that the moving components operate smoothly. By doing so, they help in extending the lifespan of these expensive machines, reducing maintenance costs, and minimizing downtime due to repairs.

bellows for cnc machine

Furthermore, bellows can also play a role in maintaining the optimal operating environment inside the machine. Some bellows are designed to work in conjunction with seals that help keep oil and lubricants from leaking out while keeping dirt and moisture at bay. This is particularly important in CNC machines, as a well-lubricated system is essential for smooth operation and accurate machining. Any compromise in lubrication due to dirt ingress could result in increased friction, overheating, and ultimately, machine failure.

Another advantage of applying bellows in CNC machines is their collapse and expansion functionality. As the moving components of the machine operate, bellows can flex and adjust to changes in position without losing their protective properties. This flexibility ensures that sensitive components remain guarded while still allowing for the necessary movement.

In terms of materials, CNC machine bellows can be manufactured from various substances, including rubber, polymers, and cloth. The choice of material can depend on the specific environment in which the machine operates. For example, environments with high temperatures might require heat-resistant materials, while those subjected to aggressive chemicals might need chemically resistant bellows.

In conclusion, bellows are a crucial component in maintaining the functionality and longevity of CNC machines. Their role in protecting sensitive machine parts from debris and contaminants cannot be overstated. As CNC technology continues to advance, the design and materials used for bellows may evolve, but their necessity will remain a constant in ensuring high performance and precision in manufacturing processes. Investing in high-quality bellows is, therefore, an essential aspect of CNC machine maintenance that manufacturers must prioritize.