Flexible Bellows Solutions for CNC Machine Protection and Longevity

The Importance of Bellows for CNC Machines

As CNC (Computer Numerical Control) machines become increasingly prevalent in various manufacturing settings, the significance of their components cannot be overstated. Among these components, bellows play a critical role in enhancing the performance and longevity of CNC machines. This article delves into the function, types, and advantages of bellows in CNC applications.

What Are Bellows?

Bellows are flexible, accordion-like structures made from various materials designed to expand and contract with movement. They serve multiple purposes such as providing protection against contaminants, accommodating lateral movement, and maintaining a controlled environment around sensitive components. In CNC machines, the primary function of bellows is to safeguard the machine's linear guides, ball screws, and other precision moving parts from debris, coolant, and grinding dust that could compromise their performance.

Types of Bellows Used in CNC Machines

There are different types of bellows designed for specific applications in CNC machinery

1. Metal Bellows Made from durable metals like stainless steel, metal bellows are often used in applications where high heat capacities and chemical resistance are essential. They provide excellent protection against harsh manufacturing environments while maintaining a compact design.

2. Rubber Bellows These bellows are more flexible and are commonly used in less demanding environments. Made from materials like neoprene or silicone, rubber bellows can absorb shock and vibration, making them ideal for protecting delicate components.

3. Plastic Bellows Often made from polyurethane or PVC, plastic bellows are lightweight and resistant to various chemicals. They offer a cost-effective solution for applications where durability and flexibility are needed without the weight and expense of metal options.

4. Custom Bellows In some cases, manufacturers require bespoke solutions tailored to their unique CNC machines. Custom bellows can be designed to meet specific dimensions, materials, and operational requirements.

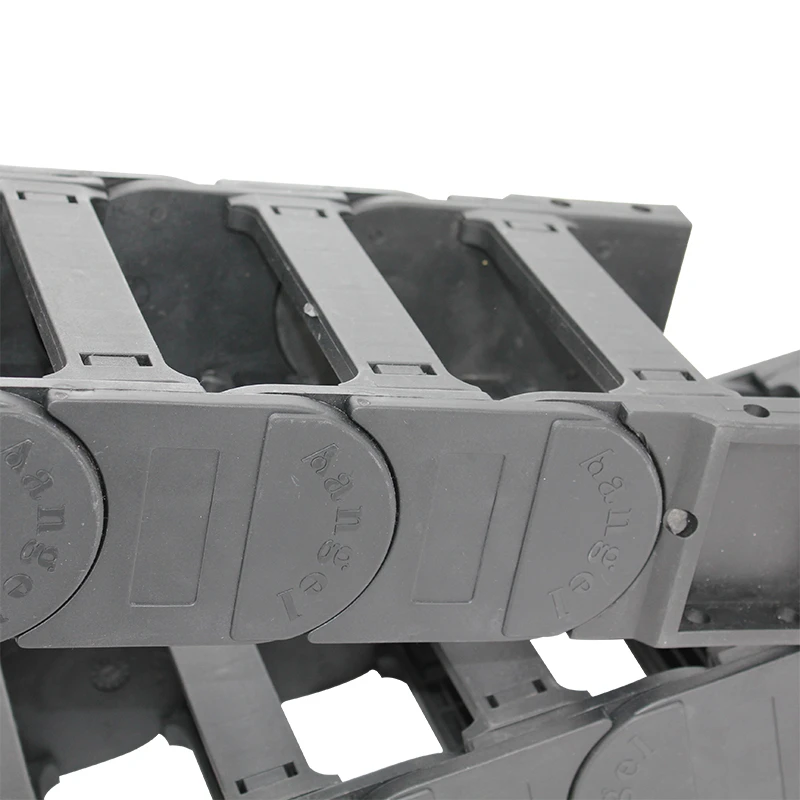

bellows for cnc machine

Advantages of Using Bellows in CNC Machines

The integration of bellows in CNC machines provides several key benefits

1. Protection Against Contamination One of the most crucial roles of bellows is to act as a shield against debris and contaminants that can enter machine parts. By preventing foreign particles from coming into contact with precision components, bellows help maintain the accuracy and reliability of CNC operations.

2. Extended Service Life By safeguarding critical machine parts, bellows help enhance the lifespan of a CNC machine. Regular exposure to dust, chips, and abrasive elements can wear down components, leading to expensive repairs or replacements. Bellows mitigate this risk and contribute to lower maintenance costs.

3. Improved Performance CNC machines that operate in clean environments tend to perform better. By reducing the likelihood of clogs and wear from contaminants, bellows ensure that machines run smoothly, which translates into higher production rates and lower downtime.

4. Compliance with Safety Standards Many industries have rigorous safety standards that mandate the protection of certain components. Bellows not only fulfill these requirements but also ensure that operations can continue safely without the risk of accidents caused by debris or spills.

5. Versatility Bellows can be adapted to various configurations and can be used in multiple applications within a CNC machine. This versatility allows them to meet the diverse needs of different industries, from aerospace and automotive to medical device manufacturing.

Conclusion

Bellows are an often-overlooked yet vital component in the world of CNC machining. Their ability to protect sensitive parts from contaminants, extend the service life of machines, and maintain high operational standards makes them indispensable in modern manufacturing environments. Investing in high-quality bellows specifically designed for CNC applications is a wise choice for businesses aiming to enhance productivity and ensure the longevity of their machinery. As technology continues to evolve, the design and materials used in bellows will also progress, contributing to even more efficient and reliable CNC operations.