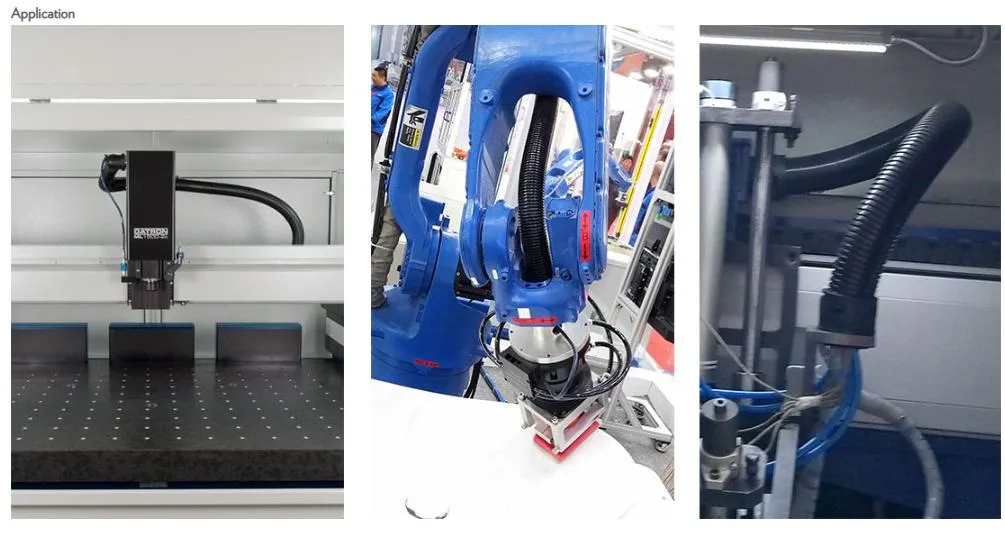

bellows for cnc machine

Bellows for CNC Machines Essential Components for Precision and Protection

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry by allowing for high precision and repeatability in machining processes. Among the critical components that enhance the functionality and longevity of these machines are bellows. These flexible and durable protective covers serve various essential roles, helping to maintain the integrity and performance of CNC machinery.

What are Bellows?

Bellows are accordion-like structures made from materials such as rubber, fabric, or metal. They can expand and contract while providing protection from dust, debris, and coolant splashes. In CNC machines, they are primarily used to safeguard sensitive components like linear guides, ball screws, and other moving parts from environmental contaminants that could impair performance and lead to costly repairs.

Importance of Bellows in CNC Machines

1. Protection from Contaminants One of the primary functions of bellows is to protect the internal components of CNC machines from chips, dirt, and other particles generated during milling, cutting, or grinding processes. Contaminants can lead to wear and tear, affecting precision and potentially causing machine failure.

2. Enhanced Durability CNC machines operate in various environments, and bellows contribute to the overall durability by shielding critical parts from harsh conditions, including coolant exposure and temperature fluctuations. This protection extends the lifespan of machine components and reduces maintenance costs.

3. Improved Safety Bellows also play a role in ensuring workplace safety. By enclosing moving parts, they minimize the risk of accidental contact, protecting operators from potentially hazardous components while maintaining machine efficiency.

bellows for cnc machine

4. Acoustic Dampening In addition to their protective functions, bellows can also dampen sound produced by the machinery during operation. This feature can help create a more pleasant working environment by reducing noise pollution, contributing to worker comfort and productivity.

Types of Bellows Used in CNC Machines

There are several types of bellows commonly used in CNC applications, each designed to meet specific needs

- Rubber Bellows Known for their flexibility and resilience, rubber bellows are prevalent in CNC machines due to their ability to withstand a wide range of temperatures and environmental conditions.

- Metal Bellows For applications requiring enhanced durability and resistance to harsh chemicals, metal bellows are often employed. They provide a robust solution, especially in high-stress environments.

- Fabric Bellows Lightweight and adaptable, fabric bellows are typically used for lighter applications. They provide adequate protection while allowing for significant movement of the machine parts.

Conclusion

In conclusion, bellows are vital components in CNC machines, providing essential protection against contaminants, enhancing durability, and improving safety. As the manufacturing landscape evolves, the design and material of bellows continue to advance, ensuring that CNC machines operate efficiently and effectively. By investing in high-quality bellows, manufacturers can enhance their CNC operations, ensuring consistent output quality and longer machine life. Understanding the importance of these components can lead to more informed decisions, ultimately impacting the productivity and profitability of manufacturing processes.