Protective Bellows for Ball Screws Applications and Benefits in Machinery Use

Bellows for Ball Screws Enhancing Precision and Protection

In the realm of precision engineering and automation, ball screws stand out as one of the most vital components in linear motion systems. Their ability to convert rotational motion into linear motion with minimal friction makes them indispensable in various applications. However, with the demanding environments in which these systems often operate, protecting them from contaminants and ensuring longevity is paramount. This is where bellows for ball screws come into play.

What Are Ball Screws?

Ball screws are mechanical devices that use a ball bearing mechanism to provide efficient linear motion. Unlike traditional lead screws, which rely purely on sliding contact, ball screws minimize wear and friction by utilizing recirculating ball bearings. This results in higher efficiency, greater load capacities, and impressive precision. Ball screws are commonly found in CNC machinery, robotics, and automation systems, where accuracy and reliability are crucial.

The Role of Bellows

Bellows serve as protective covers for ball screws, shielding them from harmful factors such as dust, dirt, coolant, and other debris. In industrial environments, these contaminants can accumulate on the ball screw, leading to wear, increased friction, and eventual failure of the system. Bellows provide a barrier, preventing foreign particles from entering the delicate spaces within the screw assembly.

Benefits of Using Bellows

1. Contamination Protection The primary function of bellows is to protect ball screws from airborne contaminants. By forming a sealed barrier, bellows help to maintain the cleanliness of the screw, ensuring that the internal components remain free from debris that could lead to malfunction or reduced performance.

2. Enhanced Durability Bellows are typically made from resilient materials that can withstand harsh conditions, including extreme temperatures, chemicals, and physical wear and tear. This durability prolongs the life of the ball screw, offering significant savings on maintenance and replacement costs.

3. Improved Performance By keeping the ball screw free from contaminants, bellows help maintain smooth operation. This ensures that machines function at optimal levels, minimizing downtime and enhancing productivity.

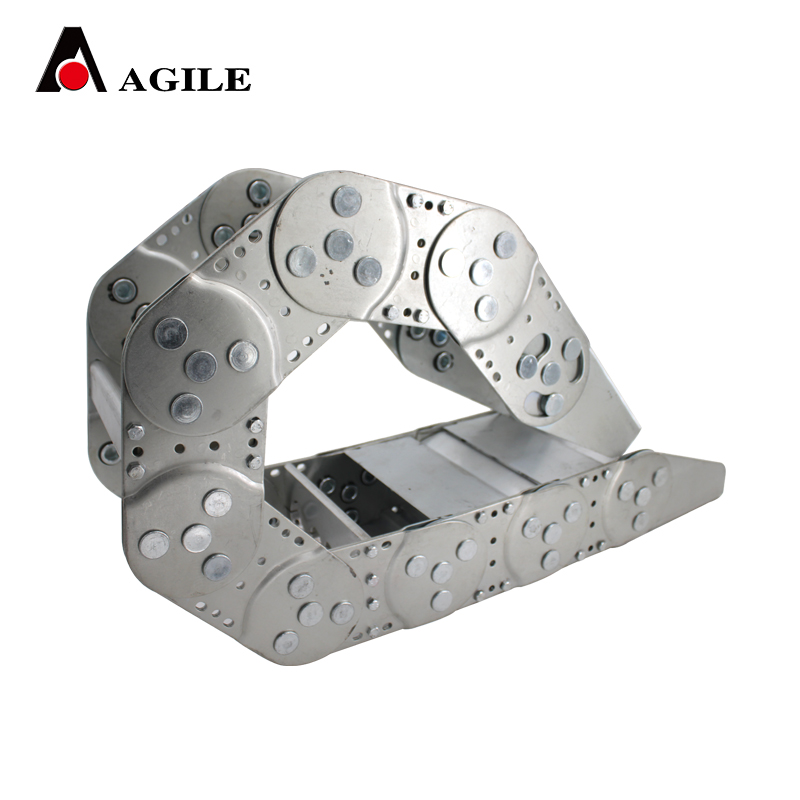

bellows for ball screw

4. Noise Reduction In addition to their protective functions, bellows can also help dampen noise produced by mechanical systems. The presence of bellows can reduce the sound generated during operation, contributing to a quieter working environment.

5. Customization Bellows can be tailored to fit specific applications and environments. They come in various sizes, shapes, and materials, allowing engineers to select the ideal bellows for their ball screw assemblies.

Material Considerations

Bellows for ball screws can be made from several materials, each offering different properties. Common materials include rubber, polyurethane, and various metals. The choice of material often depends on the operational environment

- Rubber Offers great flexibility and is commonly used for light-duty applications. - Polyurethane Provides excellent wear resistance and is suitable for moderate to heavy-duty applications. - Metal Used in extremely harsh environments, metal bellows can withstand high temperatures and pressures, although they may be less flexible than their polymer counterparts.

Installation and Maintenance

Proper installation of bellows is crucial for their effectiveness. They should be securely attached at both ends of the ball screw to ensure a complete seal. Additionally, regular inspections should be performed to check for signs of wear or damage. Maintaining the integrity of the bellows will directly impact the performance and longevity of the ball screw system.

Conclusion

Bellows for ball screws are more than just protective components; they are essential pieces of engineering that ensure the reliability and efficiency of linear motion systems. By safeguarding ball screws from contaminants and enhancing their performance, bellows contribute significantly to the overall functionality of machinery. As industries continue to evolve and demand higher precision and reliability, the importance of bellows will only continue to grow. Investing in quality bellows for ball screws is an investment in the future of any machine, ensuring longevity, efficiency, and enhanced performance in an increasingly competitive market.