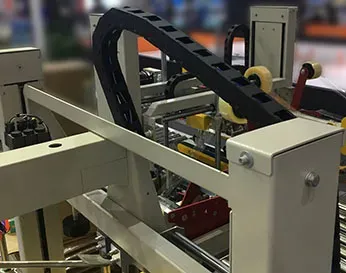

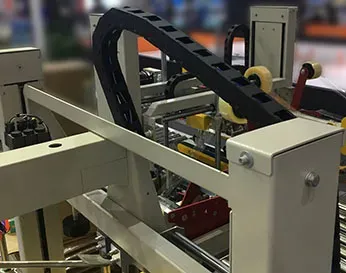

Bellows for protecting against the intrusion of dust and debris on equipment

Dust cover bellows are essential components in many mechanical systems, providing protection from dust, dirt, and debris. These bellows are typically made from flexible materials such as rubber or plastic, and are designed to expand and contract as needed to accommodate the movements of the machinery they are installed on.

One of the primary functions of dust cover bellows is to prevent contamination of sensitive components within a mechanical system. Dust and debris can cause friction, wear, and damage to moving parts, leading to increased maintenance costs and potential breakdowns. By encasing these components in a dust cover bellows, they are shielded from external particles, ensuring smooth operation and extending the lifespan of the machine.

In addition to protection from contaminants, dust cover bellows also serve to maintain proper lubrication of moving parts. Dust and debris can mix with lubricants, forming a gritty paste that can compromise the efficiency of the system. By sealing off critical components with a bellows, the lubrication remains clean and uncontaminated, allowing for optimal performance and reduced maintenance requirements.

Furthermore, dust cover bellows can also provide a degree of thermal insulation for machinery operating in high-temperature environments. The flexible material of the bellows acts as a barrier, preventing heat transfer to sensitive components and helping to regulate temperature within the system

dust cover bellows. This can improve overall efficiency and prevent overheating, which can lead to premature component failure. In certain applications, dust cover bellows are also used to contain harmful substances or protect against chemical exposure. For example, in industrial settings where corrosive materials are present, bellows made from chemical-resistant materials can shield machinery from deterioration and ensure the safety of workers. Overall, dust cover bellows play a crucial role in maintaining the integrity and performance of mechanical systems. Whether they are used to protect against dust, maintain lubrication, provide thermal insulation, or shield against hazardous substances, these components are essential for ensuring the longevity and efficiency of machinery. In conclusion, dust cover bellows are versatile and indispensable components in a wide range of mechanical applications. Their protective qualities safeguard sensitive machinery from contaminants, maintain proper lubrication, provide thermal insulation, and offer protection against chemical exposure. By integrating dust cover bellows into mechanical systems, engineers can enhance performance, reduce maintenance costs, and prolong the lifespan of their equipment.

dust cover bellows. This can improve overall efficiency and prevent overheating, which can lead to premature component failure. In certain applications, dust cover bellows are also used to contain harmful substances or protect against chemical exposure. For example, in industrial settings where corrosive materials are present, bellows made from chemical-resistant materials can shield machinery from deterioration and ensure the safety of workers. Overall, dust cover bellows play a crucial role in maintaining the integrity and performance of mechanical systems. Whether they are used to protect against dust, maintain lubrication, provide thermal insulation, or shield against hazardous substances, these components are essential for ensuring the longevity and efficiency of machinery. In conclusion, dust cover bellows are versatile and indispensable components in a wide range of mechanical applications. Their protective qualities safeguard sensitive machinery from contaminants, maintain proper lubrication, provide thermal insulation, and offer protection against chemical exposure. By integrating dust cover bellows into mechanical systems, engineers can enhance performance, reduce maintenance costs, and prolong the lifespan of their equipment.