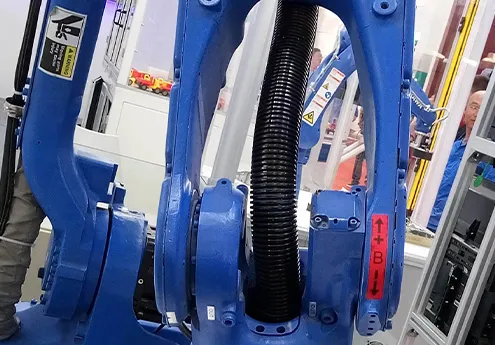

bellows for cnc machine

The Importance of Bellows for CNC Machines

CNC (Computer Numerical Control) machines are vital in modern manufacturing, enabling precision machining that has revolutionized industries such as aerospace, automotive, and electronics. One often-overlooked component that plays a crucial role in the operation and longevity of these machines is the bellows. These protective covers are essential for maintaining the integrity and performance of CNC machinery, and understanding their function can help manufacturers make more informed decisions regarding equipment maintenance and longevity.

The Importance of Bellows for CNC Machines

Moreover, bellows help maintain the machine’s accuracy by preventing chips and lubricants from entering critical areas. This protection is vital because even minuscule contaminants can lead to significant deviations in machining precision. With tighter tolerances in manufacturing today, ensuring that CNC machines operate at their peak is imperative, and bellows help facilitate this through robust protection.

bellows for cnc machine

Another significant aspect of bellows is their ability to provide a degree of flexibility to the machine, allowing for smooth movement of the machinery parts while ensuring that they are shielded from environmental factors. Typically made from materials like rubber, polyurethane, or PVC, bellows can endure the stresses of constant movement while maintaining their shape and function. This flexibility is also crucial for accommodating different machining operations that require varying levels of exposure to environmental conditions.

The installation and maintenance of bellows are also essential for optimal CNC performance. Regular inspections should be conducted to look for signs of wear, cracking, or any other damage. Replacing worn-out bellows promptly not only prolongs the machine's lifespan but also enhances operational efficiency. Neglecting this critical component can lead to more severe issues that result in expensive repairs or replacements of larger machine parts.

In conclusion, the bellows for CNC machines are vital components that help ensure the efficiency, accuracy, and longevity of the equipment. By protecting sensitive mechanical parts from contaminants and providing stability during operations, bellows significantly contribute to the overall performance of CNC machines. Manufacturers should prioritize the maintenance and replacement of these protective covers to prevent unnecessary downtime and to minimize repair costs. Ultimately, investing in high-quality bellows and ensuring their regular upkeep is a smart approach for any business looking to optimize its CNC machinery and improve its bottom line.