Exploring Themes and Insights from the Cover Material Analysis

Bellow Cover Material An Exploration of its Significance and Applications

In the realm of engineering and material science, the term bellow cover material often surfaces in discussions about various applications requiring flexibility, durability, and resistance to environmental factors. A bellow cover is a type of flexible protective enclosure that is used to safeguard mechanisms, components, and joints in machinery, vehicles, and numerous industrial applications. This article will delve deeper into the significance of bellow cover materials, their composition, and their diverse range of applications.

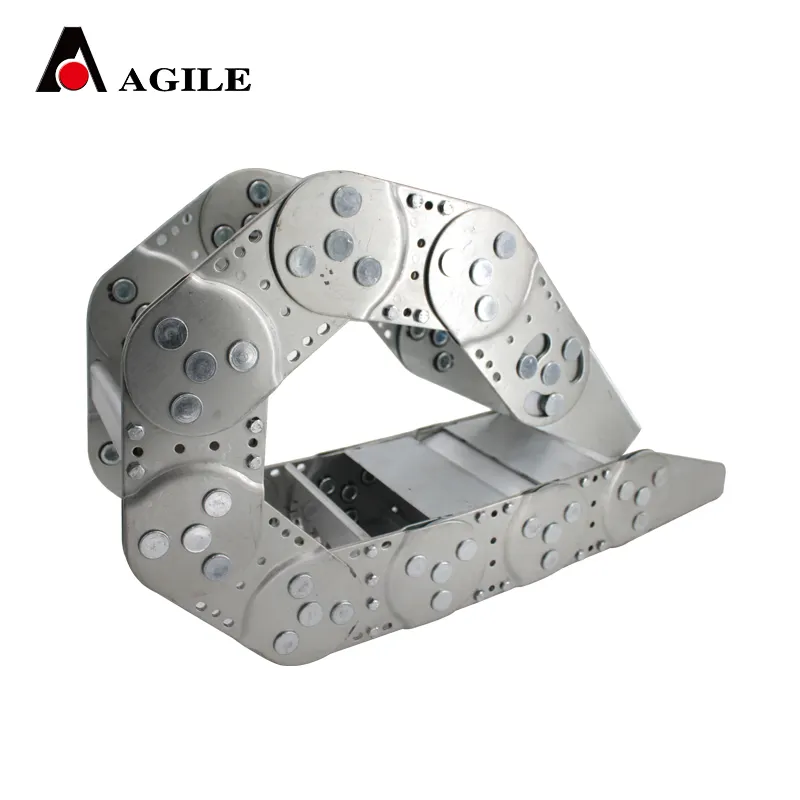

Bellows are typically characterized by their accordion-like structure, allowing for expansion and contraction as required by the movement of the components they encase. The materials used in manufacturing bellows must exhibit not only flexibility but also resilience against wear and tear. Common materials include rubber, various plastics, and metals, each serving distinct applications based on their intrinsic properties. For instance, rubber bellows are often utilized in automotive applications due to their excellent shock-absorbing qualities, whereas metal bellows are chosen for high-pressure environments such as in aerospace or pipeline systems due to their strength and durability.

One of the primary functions of bellow cover materials is to provide protection against external elements. In industrial settings, components are frequently exposed to dust, moisture, chemicals, and extreme temperatures. A high-quality bellow cover can effectively shield sensitive parts from these hazards, thus extending their lifespan and reducing maintenance costs. Furthermore, bellows can help contain lubricants and hydraulic fluids, preventing leakage and ensuring optimal functionality.

bellow cover material

The versatility of bellow cover materials is evident in their wide-ranging applications. In the automotive industry, bellows are found in steering systems, exhaust systems, and suspension components, where they absorb vibrations and compensate for movement. In the realm of manufacturing and robotics, bellows protect linear guides, screws, and other moving parts from contaminants, ensuring precise operation and longevity. Additionally, bellows play a critical role in medical devices, providing flexible connections in systems that require sterile environments, such as surgical equipment and diagnostic devices.

Moreover, the design of bellow cover materials can be tailored to meet specific requirements. For instance, custom shapes and sizes can be produced to fit a variety of applications, allowing for greater flexibility in design and functionality. Engineers and designers collaborate closely to identify the best materials and configurations, taking into account factors such as pressure, temperature, and intended movement.

The benefits of utilizing bellow cover materials go beyond mere protection and flexibility. They are also instrumental in reducing noise and vibration in mechanical systems, contributing to a smoother and quieter operation. This aspect is particularly valuable in sensitive environments such as laboratories, hospitals, and residential areas, where excessive noise can be detrimental to work and living conditions.

In conclusion, bellow cover material is a critical component in various industries, offering essential protection and flexibility for moving parts and mechanisms. From automotive to medical applications, the choice of material along with thoughtful design considerations plays a pivotal role in ensuring functionality, longevity, and performance. As technology advances and the demand for innovative solutions grows, the evolution of bellow cover materials will continue to pave the way for enhanced efficiency and reliability in countless applications. The ongoing development in this field signifies the importance of material science in addressing the challenges faced across different sectors, reinforcing the need for high-quality, engineered solutions.