bellow cover manufacturer

The Evolution of Below Cover Manufacturers Meeting Modern Demands

In the ever-evolving landscape of manufacturing, the role of below cover manufacturers has become increasingly significant. These manufacturers specialize in producing protective covers used in various industries, including automotive, electronics, and outdoor equipment. As consumer expectations rise and technology advances, below cover manufacturers are challenged to innovate and adapt to meet modern demands.

Understanding Below Covers

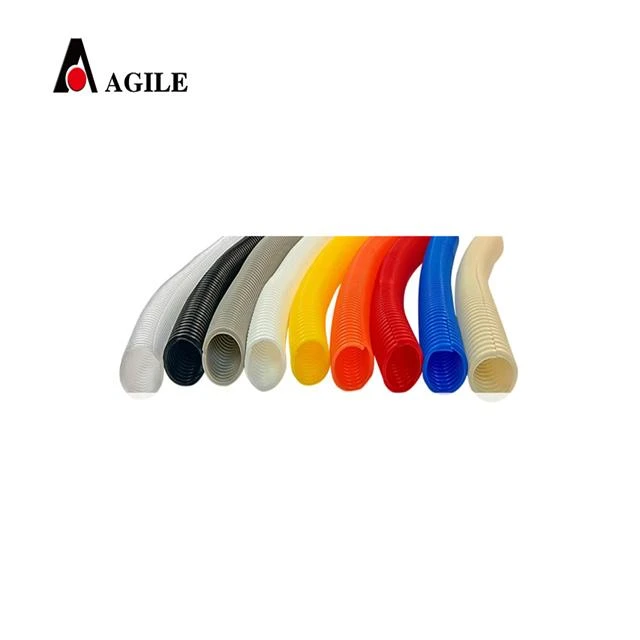

Below covers are protective coverings designed to shield products from environmental factors such as dust, moisture, and physical damage. They play a critical role in extending the lifespan of equipment and ensuring reliable performance. These covers come in various materials, including polyethylene, vinyl, and custom-engineered fabrics, each providing unique benefits depending on the intended use.

Industry Demand and Trends

With the surge in e-commerce and online shopping, there has been a significant increase in the demand for protective packaging solutions. Consumers now prioritize the safety and durability of products during transit and storage, prompting manufacturers to reassess their approaches. Below cover manufacturers have responded to this demand by focusing on lightweight yet durable materials that can withstand harsh handling and environmental conditions.

Moreover, sustainability has become a key consideration for manufacturers and consumers alike. The industry is gradually shifting towards eco-friendly materials and practices. Below cover manufacturers are now exploring biodegradable and recyclable options, aligning production processes with environmental sustainability goals. This shift not only meets consumer preferences but also addresses regulatory pressures aimed at reducing plastic waste.

bellow cover manufacturer

Technological Innovations

Advancements in technology are transforming the way below covers are designed and manufactured. Innovative techniques such as 3D printing are allowing for the creation of custom covers that perfectly fit unique products. This technology reduces material waste and increases efficiency, enabling manufacturers to produce tailored solutions with speed and precision.

Furthermore, the integration of smart technologies, such as RFID tags, into below covers is gaining traction. These tags can provide real-time data on the condition of the product beneath the cover, alerting stakeholders to potential issues before they become critical. This not only enhances the overall reliability of products but also improves inventory management and logistics.

Challenges Ahead

Despite the promising advancements, below cover manufacturers face several challenges. One of the primary hurdles is the volatility of raw material prices, which can significantly affect production costs. Manufacturers must develop strategies to mitigate these risks while maintaining competitive pricing. Additionally, keeping pace with rapidly changing consumer trends and technology can strain smaller manufacturers who may lack the resources to invest in new innovations.

Conclusion

Below cover manufacturers play a pivotal role in the modern manufacturing ecosystem. As they navigate the complexities of consumer demands, technological changes, and sustainability initiatives, they are poised to shape the future of protective coverings. By embracing innovation and prioritizing quality, these manufacturers can continue to provide essential solutions that meet the needs of both industries and consumers alike. The road ahead may have its challenges, but the commitment to excellence in manufacturing will undoubtedly lead to a more resilient and sustainable future.