Understanding the Importance of Bellows in Ball Screw Mechanisms

The Importance of Ball Screw Bellows in Precision Machinery

In the world of precision machinery, the components that facilitate movement and accuracy are crucial. Among these components, ball screws and their protective coverings, known as bellows, play an essential role. Understanding the function and significance of ball screw bellows is vital for anyone involved in machine design, manufacturing, or maintenance.

What Are Ball Screws?

Ball screws are a type of mechanical device used to convert rotational motion into linear motion with minimal friction. They consist of a threaded shaft and a ball nut that engages with the threaded shaft's grooves. As the shaft rotates, the balls move along the grooves, allowing the nut to travel linearly. Ball screws are renowned for their high efficiency, precision, and repeatability, making them indispensable in various applications, including CNC machines, robotics, and automation systems.

The Role of Bellows

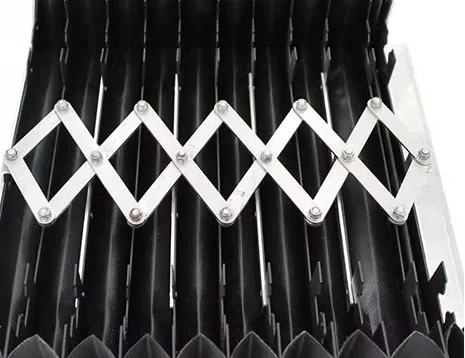

While ball screws are designed for precision, they are also susceptible to damage from external contaminants such as dust, dirt, and moisture. This is where ball screw bellows come into play. Bellows are flexible, accordion-like covers that protect the ball screw assembly from debris and other environmental factors that can impair its functionality. Typically made from durable materials such as polyurethane, rubber, or fabric, bellows are designed to withstand harsh conditions while maintaining flexibility and resilience.

Key Functions of Ball Screw Bellows

1. Protection from Contaminants The primary function of ball screw bellows is to shield the internal components from external particles. By preventing the ingress of dust and debris, bellows help maintain the operational integrity and longevity of the ball screw.

2. Moisture Resistance In environments where moisture is a concern, bellows act as a barrier against humidity and liquid exposure. This is particularly important in metalworking and manufacturing applications where coolant and lubricants are used.

ball screw bellows

3. Preventing Wear and Tear Continuous exposure to contaminants can lead to increased wear on the ball screw and its associated components. By providing a protective layer, bellows help to reduce friction and wear, thus enhancing operational efficiency and extending the lifespan of the machinery.

4. Maintenance Reduction With bellows in place, the frequency of maintenance and cleaning can be significantly reduced. This not only saves time and resources but also minimizes downtime in production environments, thereby improving overall productivity.

5. Aesthetic Value Although primarily functional, bellows also provide a polished appearance to machinery. A well-designed ball screw assembly with bellows can enhance the overall look of the equipment, making it more appealing in a showroom or workspace.

Selection and Installation Considerations

When choosing ball screw bellows, several factors should be taken into consideration, including the type of environment in which the machinery operates, the size and stroke of the ball screw, and the specific materials best suited for the application. A proper installation is also crucial; bellows should be securely attached to prevent any gaps that could allow contaminants to enter.

Additionally, periodic inspection of the bellows is important to ensure they remain intact and functional. Any signs of wear, cracking, or tearing should prompt immediate replacement to maintain the protective integrity of the ball screw assembly.

Conclusion

In summary, ball screw bellows are a critical component in the realm of precision engineering and machinery. They provide essential protection against contaminants, moisture, and wear, thereby enhancing the performance and longevity of ball screw systems. As industries continue to push the boundaries of speed and precision, the role of bellows will remain pivotal in ensuring that machinery operates smoothly and efficiently. For engineers and manufacturers, investing in high-quality ball screw bellows is a wise decision that pays off in improved performance and reduced maintenance costs.